Lead Center Special Sealing Industry scores with new orders in the food and beverage industry.

The market is challenging like few others. In the diverse applications of the food and beverage industry, the main focus is on maximum product safety through mechanically and chemically resistant special materials and geometries in hygienic design. Extreme temperatures, high pressures, grease, acids, high-friction media and challenging cleaning agents and methods present seals with difficult tests.

Harmful substances must not be allowed to escape from the sealing materials, nor must microorganisms be allowed to accumulate in unwanted crevices. In beverage bottling plants, it is also important to prevent the transfer of flavors from one batch to the next: The mineral water bottled today must not taste like the sweet lemonade processed yesterday. Regulatory requirements are also very important. They are particularly strict in the food and beverage industry. Around the globe, a wide variety of conformities must be observed for the materials used, some of which differ from region to region of the world and also change frequently.

But the higher the demands, the greater the opportunities for a sealing specialist like Freudenberg Sealing Technologies (FST). The best examples of this are orders that the Lead Center (LC) Special Sealing Industry (SSI) has recently received from two major customers in the industry: Thermoplan and Alfa Laval.

XP sleeves for Thermoplan

Thermoplan is a Swiss manufacturer of professional coffee machines for hotels and restaurants. Among other things, the company equips the world’s largest coffee house chain. In its branches, thousands of cups are prepared every day as Americano, espresso, cappuccino, latte macchiato and many more. To do this, the brewing chamber of the coffee machines must be sealed – reliably and permanently, cup after cup. A leak in the piston, which compresses the coffee powder in the brewing chamber and seals the chamber during brewing, could mean: “This store will remain closed today”.

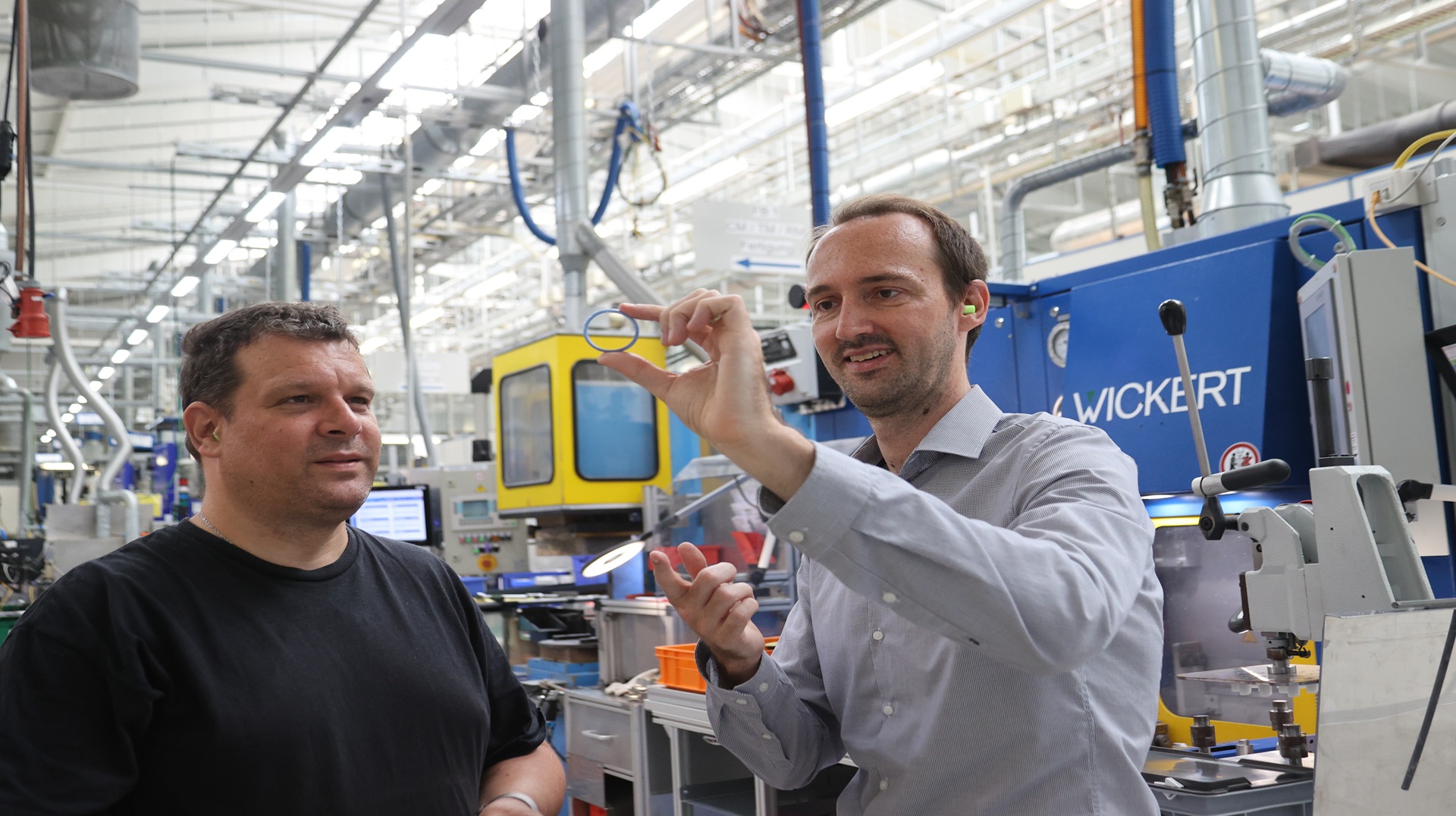

“Previously, a competitor supplied this seal. However, it lost the approval for its elastomer and was unable to offer an adequate alternative material,” Tobias Weißenberger, Product Manager LC SSI, says. In its “Hygienic Line”, FST had a tried-and-tested material on hand, that could withstand the high loads on the brewing chamber and also complied with the regulations of all relevant regions of the world: ®Fluoroprene XP.

Product developer Frank Lauer says: “Everything was extremely urgent. We turned the first samples from blanks using Freudenberg Xpress®. At the same time, we did our utmost to build a tool very quickly. We were able to deliver tool-ready parts within three weeks.” Using the finite element method (FEM), the Lead Center was also able to calculate an optimized modification of the seal for the new sleeve in collaboration with Freudenberg Technology Innovation (FTI).

This fast-paced tour de force has paid off: FST was not only awarded the major contract, but is also involved in three other Thermoplan development projects. “It was classic ‘Innovating Together’ between our Lead Center and the customer, our sales company in Switzerland, Freudenberg Xpress, FST Toolmaking and FTI,” says Weißenberger.

Flange connections for Alfa Laval

The same applies to the sales success of the SSI lead center with Alfa Laval, a Scandinavian manufacturer of components for beverage filling systems, among other things. Here, too, FST was able to replace a competitor. The gaskets in its flanges used as pipe connectors were unable to confirm the “triple conformity” required by the customer. In other words, they no longer met the industry regulations applicable in America, Europe and China at the same time.

“When the contract was re-tendered, our samples performed best in the customer tests,” Lauer says. In this case, an EPDM material from FST’s “Hygienic Line” was the trump card. This is now being used in 15 different flange dimensions from Alfa Laval. “We are now also potentials for other projects with this customer. The business relationships are becoming closer and closer,” Weißenberger says.

For both Thermoplan and Alfa Laval, it was helpful for the LC SSI that the customers were already working with other FST Lead Centers. Thermoplan, for example, uses O-rings from Freudenberg, while Alfa Laval uses diaphragms.

For further questions, please get in touch with Stefan.Huser@fst.com, Mikkel.Kornerup@fst.com, frank.lauer@fst.com or Tobias.Weissenberger@fst.com.