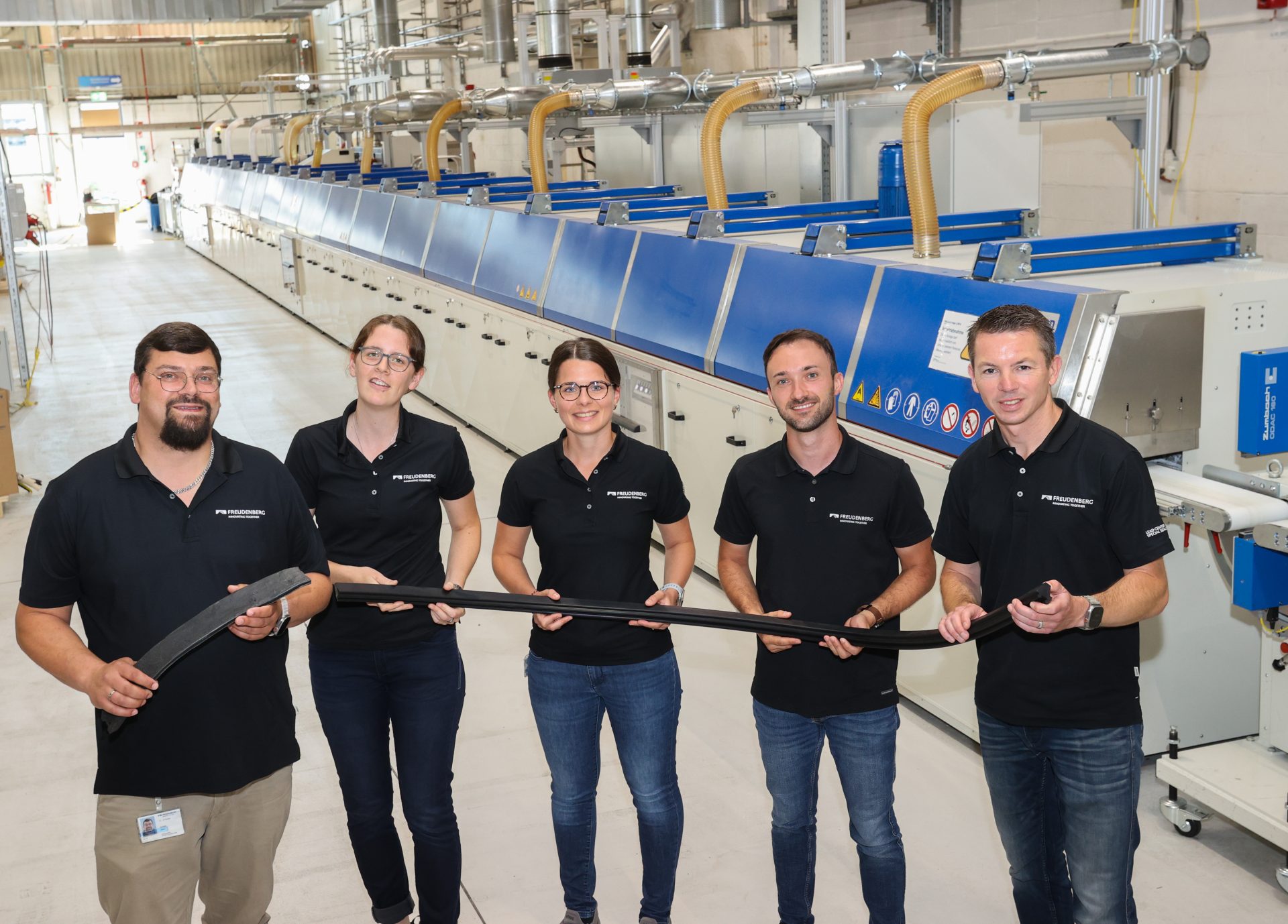

Lead Center Special Sealing Industry breaks new ground in terms of process technology and commissions an extrusion line for sealing profiles using molten salt for vulcanization.

In Brief

The focus of the new system is on large-scale applications with challenging conditions, such as the energy sector, food and beverage industry, and mechanical engineering.

Lead Center Special Sealing Industry (SSI) has introduced a new extrusion line for sealing profiles using molten salt for vulcanization, marking a significant advancement in process technology.

The new extrusion line allows for the production of sealing profiles using a completely new process for Freudenberg, enabling the use of a wider variety of materials and opening up new markets.

The Liquid Curing Method (LCM) involves vulcanizing extruded profiles in molten salt at around 392 degrees F, ensuring even heat transfer without undesirable contact with oxygen.

The new system, LCM 19, is a sustainable, self-contained system that recycles salt and water, making it environmentally friendly. It also features two mobile extruders with different diameters for flexibility and quality.

When André Schmitt, Manager Operations, Extrusion Technologies Weinheim, talks about the new extrusion line in Building 197, he quickly starts to enthuse. “This is fundamental for us, a milestone, a big step towards the future. The system enables us to produce sealing profiles using a completely new process for Freudenberg. We can now process a much wider variety of materials and thus open up new markets.” Profiles from Freudenberg Sealing Technologies (FST) are currently used, for example, in roller bearings for wind turbines.

Until now, the Lead Center Special Sealing Industry (SSI) has used two methods to produce sealing profiles. In continuous extrusion, the profile is vulcanized directly in the system in an automated process. The cross-linking process takes place – as the name suggests – in a continuous process. To do this, the profile is passed through a microwave with ultra-high frequency (UHF) radiation and a hot air channel. No post-curing required, the product comes out of the system ready for dispatch. In the second process, discontinuous extrusion, the extruded profiles are placed on a tray in their raw state, then vulcanized with steam in autoclaves, similar to a pressure cooker, and finally washed and finished.

The continuous process offers many advantages thanks to its high degree of automation: high process stability, consistently high part quality and short throughput times. However, not all materials can be vulcanized in the microwave. It works excellently for materials cross-linked with sulphur. However, as soon as materials use peroxides for cross-linking, they react unintentionally with the atmospheric oxygen in the microwave and form a sticky surface.

Like deep-frying in the kitchen

The Liquid Curing Method, or LCM for short, has proven a solution. The “liquid” used for vulcanization is liquid salt. In this continuous process, the extruded profile is vulcanized in molten salt at around 200 degrees Celsius (392 degrees F). The salt ensures an even heat transfer without the undesirable contact with oxygen. “This is comparable to deep-frying in the kitchen. Only we don’t use hot oil, but hot salt,” Schmitt says.

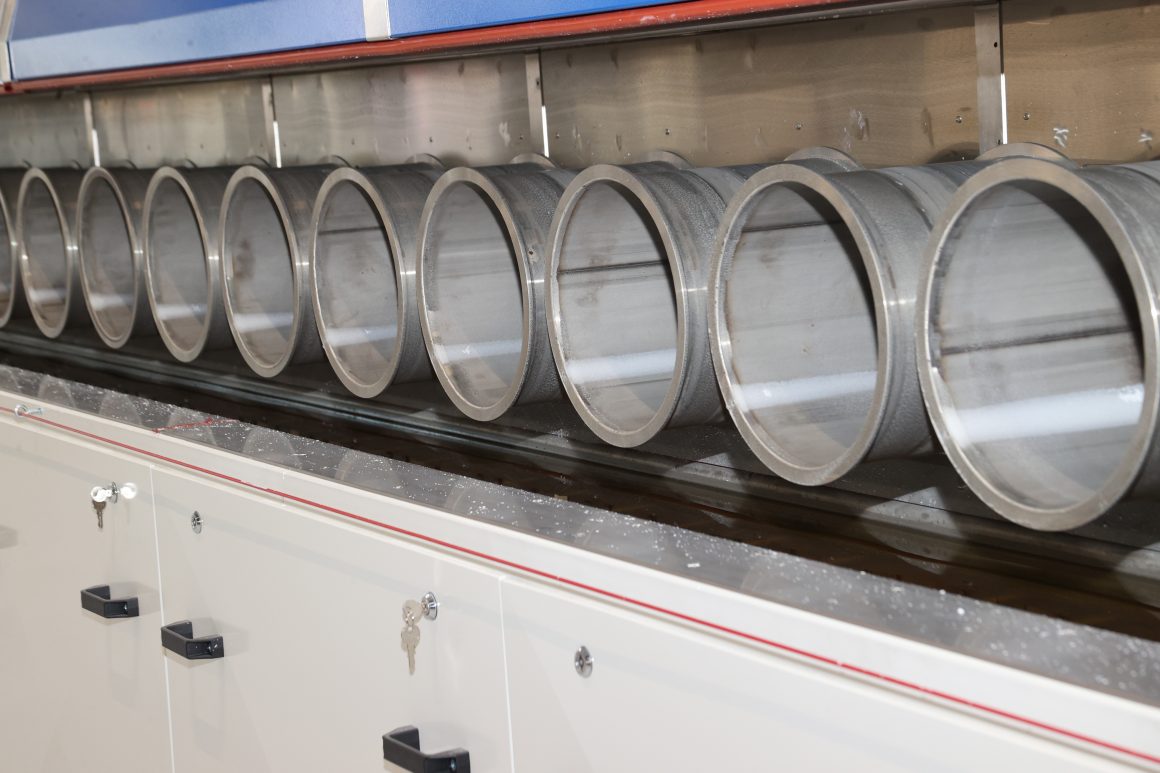

The salt pan in the new FST system measures 19 meters in length – which explains the figure in its name, LCM 19. In total, the entire system stretches an impressive 36 meters along almost the entire wall of the hall. The centerpiece is the salt bath, which is divided into two sections. On the seven-metre-long trickle section, the profile is first “showered” with hot liquid salt, which vulcanizes the outer skin. This ensures dimensional stability before the profile is completely immersed in the hot salt in the next process step and pulled over the twelve-metre-long roller section in the tub.

The profile is then shaken on the beater section so that the liquid salt falls off. This is followed by a combined washing, cooling and blow-off section, where the remaining salt is removed and the profile is cooled to room temperature.

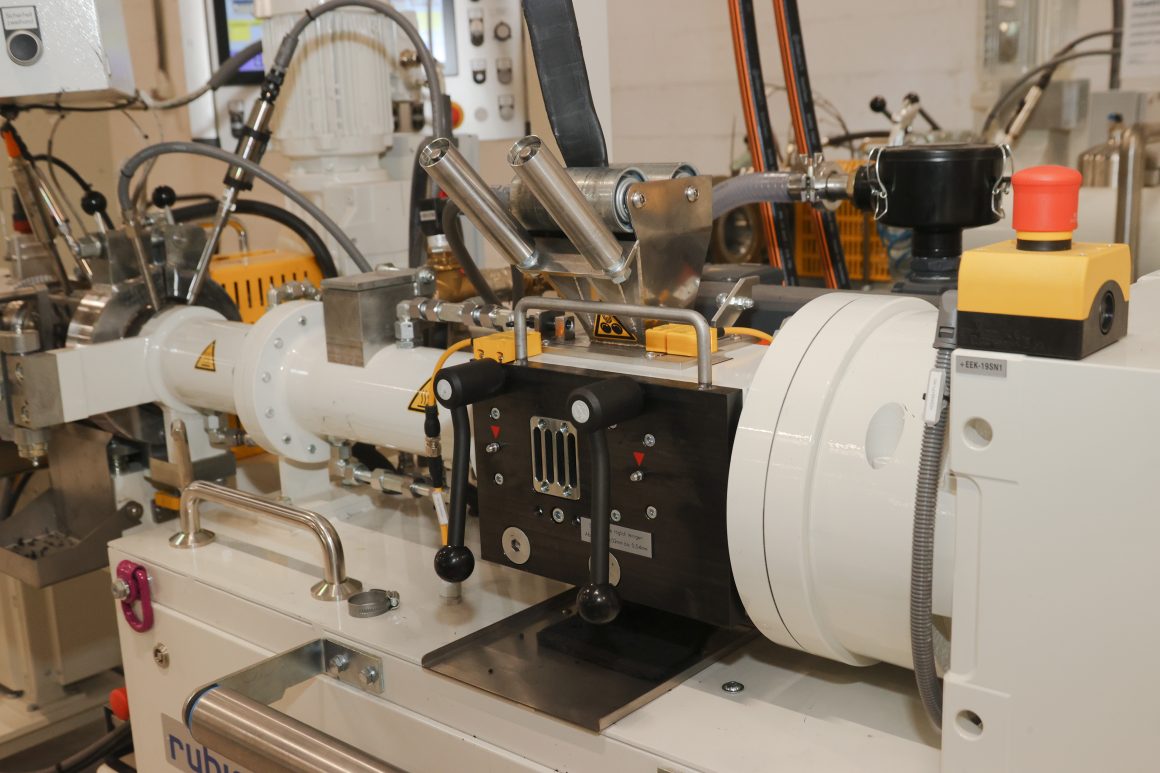

Two extruders

The so-called caterpillar haul-off is located at the very end of the system as a drive element. At the very beginning is the extruder. Important to mention in terms of flexibility and quality: The new line even has two mobile extruders. They have different diameters – for filigree profiles as well as filigree to huge cross-sections. Both extruders are also equipped with gear pumps. These units compensate for pressure fluctuations during extrusion and thus ensure an even material flow.

Important from an environmental point of view: The entire LCM 19 is a self-contained system. Salt and washing water are recycled, fed back into the process and reused.

“We now have access to all common extrusion processes, which we can use depending on customer requirements. This gives us more flexibility in material selection and development for new applications. We can now work with all common materials,” says Schmitt. This means that customers can access an expanded portfolio of high-quality Freudenberg materials that they may already be familiar with from the molding process. Many of these materials have approvals for certain applications, for example FDA approval from the US Food and Drug Administration (FDA), which qualifies the seals to be marketed in the American food and beverage industry in the first place. In a nutshell: FST can now market its material competence and its expertise in application and design coupled with the manufacturing competence from the salt bath.

The new system was delivered at the beginning of April, then assembled, safety-checked and tested in numerous trials. Larger quantities for the first customer orders are to be produced shortly. A new focus and product range is now, for example, profiles that seal the cells of electrolysers. This requires high resistance to alkalis and oxygen, which Freudenberg materials can provide.

The focus is on large-scale applications with challenging conditions that require high-quality materials. These include the energy sector with hydrogen applications and offshore wind turbines as well as the food and beverage industry and mechanical engineering. One example of this is large lid seals in soldering systems that are exposed to high temperatures and aggressive vapors.