The Powertrain partner production team in Bursa finds creative solutions to optimize the loading capacity of trucks

In logistics, every cubic meter of space counts. Empty runs or underutilized truck loading areas increase a company’s carbon footprint. If, on the other hand, loading capacities are perfectly utilized, this can reduce the number of transports, lower costs and thus increase efficiency.

The team at partner production Powertrain in Bursa recently mastered a project to find the ideal loading method for the site’s products. “Our first idea was to increase the number of boxes per pallet. However, this was not what our customers wanted, as it could have had an impact on the minimum order quantities,” Project Manager İsmail Demir says.

The challenge

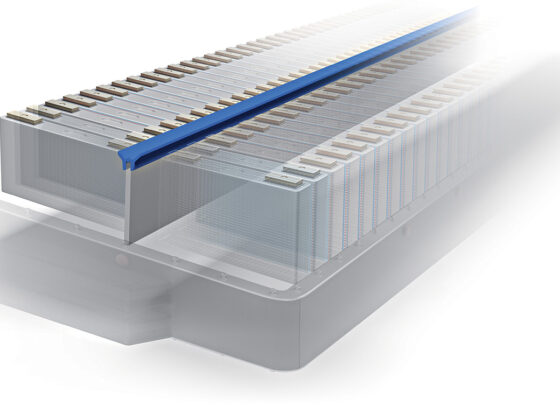

Previously, the loading height of the trucks used was limited to 2.80 meters due to the opening of the loading doors. As a result, only two rows of pallets could be stacked on top of each other, even though there was still room in the storage space of the truck itself. This means that the vehicle’s loading capacity was not fully utilized, which is inefficient.

The creative solution

“To solve the problem, we made a mechanical modification to the truck loading door. This allowed it to open differently, which means we can now use the full three meters of loading height,” says Demir. In other words, an additional 37 cubic meters of loading space is now available for each journey. “Instead of the previous 31,680 units, we can now transport 46,080 with each trip.” This corresponds to an increase of around 45 percent.

The more efficient logistics do not only reduce the CO2 footprint, but also the unit costs. The project demonstrates how strategically improved loading performance can not only reduce costs, but also improve sustainability aspects in the supply chain.

“We have scrutinized our traditional loading methods and achieved many advantages with small but effective changes. Nevertheless, we are not resting on our laurels, but are keeping at it and continuing to optimize,” says Demir.

Göksel Aydın and Ecem Balkın)