The Lead Center Fluid Power Industry has once again demonstrated its problem-solving expertise. The team in Schwalmstadt has developed a wiper that is being used on pistons in Wacker vibrating plates. It protects the throttle lever of the shaker from dust, keeping it from clogging and ultimately breaking down.

Munich-based Wacker Neuson specializes in construction equipment and compact machinery.

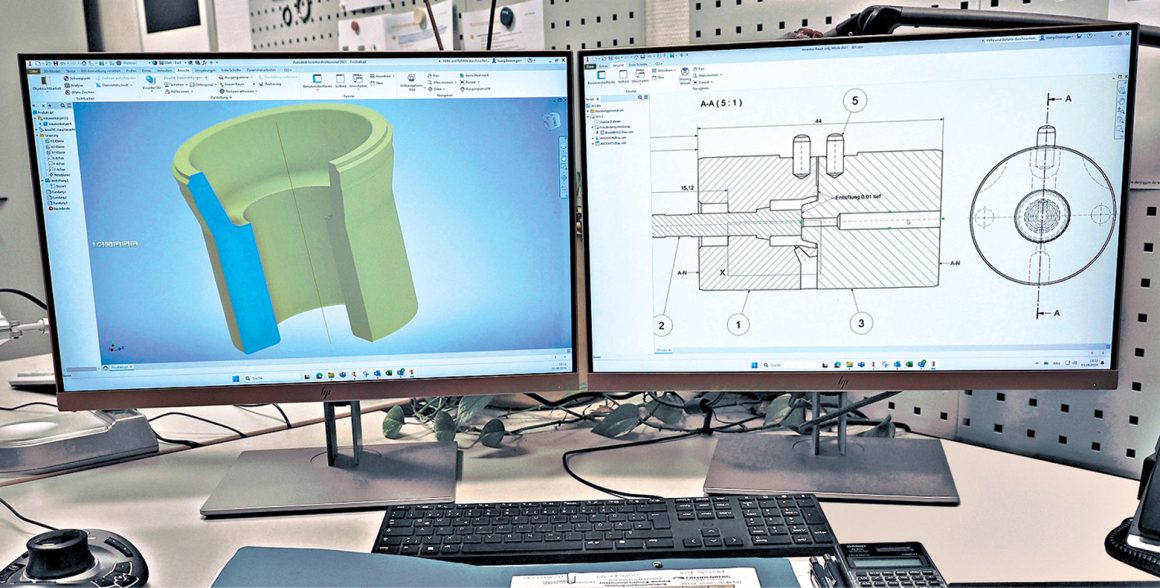

Early this year, the company contacted Freudenberg. Breakdowns were piling up for a current series of gasoline-powered vibrating plates. The problem was the swirling dust that affected the throttle lever over time. This led to deteriorating operation and even to complete clogging. In Schwalmstadt, Gonzalo Barillas, Manager Engineering, and Simon Biesenroth, Professional Product Marketing, Lead Center Fluid Power Industry, analyzed the problem.

Simon Biesenroth, Professional Product Marketing in Schwalmstadt.

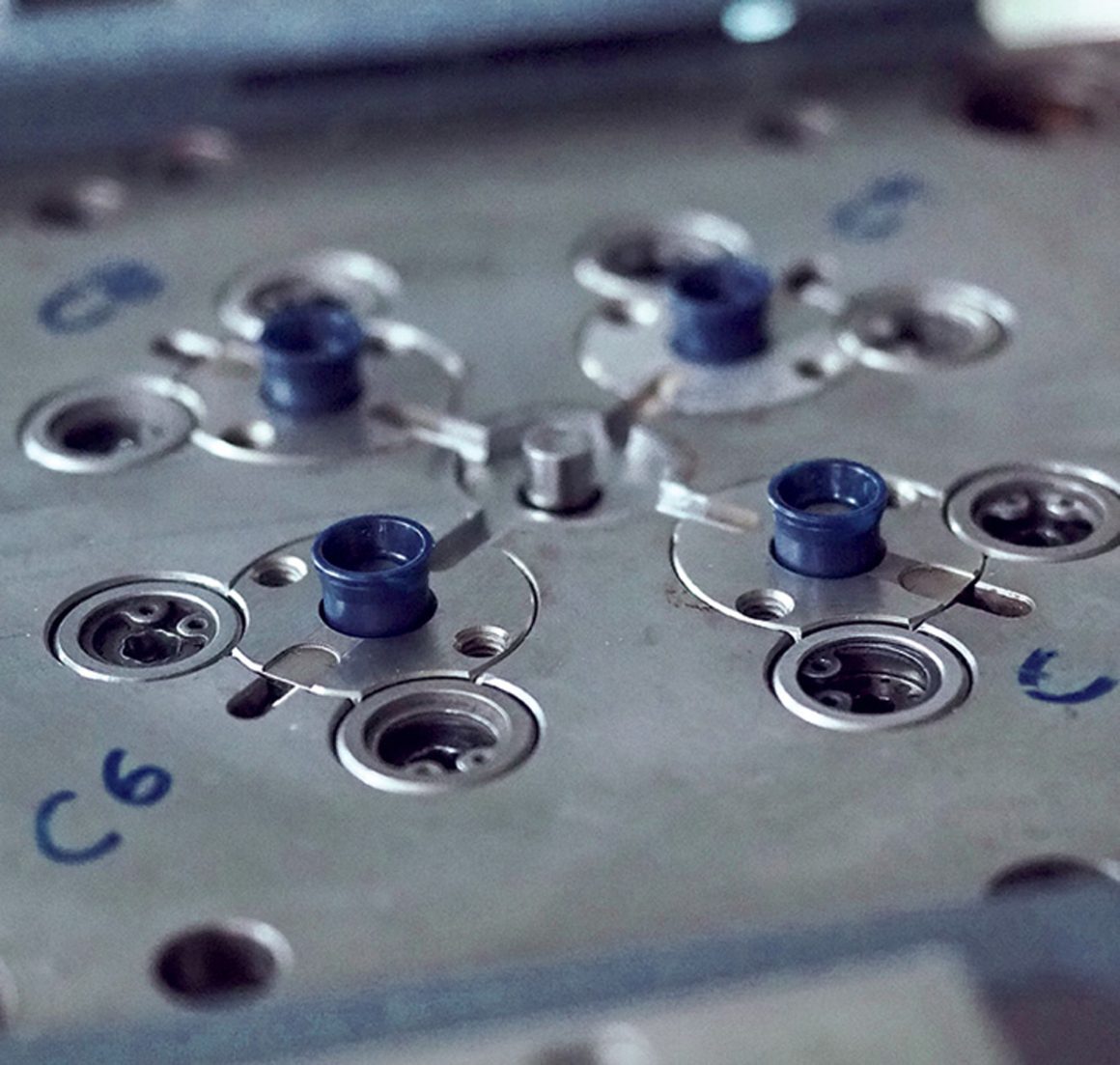

“The main function of the throttle lever is the manual dosing of the fuel feed,” said Biesenroth. “In the original piston design, two O-rings made of chemically resistant material were used to seal the fuel area, but there was nothing to protect the piston from contamination. Our proposed solution was to adapt the piston design and place a simple wiper inside on the piston, which seals the piston at two main contact points and thus keeps dirt out.”

The team used simulations to optimize the design, and then Wacker Neuson tested the first Xpress sample. The testing yielded impressive results. Since the wiper had to be very small to fit in the installation space. it was essential to clarify whether the Lead Center could actually build it in the first place. The production tests went well, and the customer was given the first prototypes for more testing.

“But when the prototypes were tested, the parts slid off the piston during operation because of their smooth surface,” Biesenroth said. “The solution was the placement of a restraint on the piston, without changing the design of the seal. The customer was interested in a quick solution to keep production of the current series rolling. Thanks to good cooperation between toolmaking, production and the sampling and release processes, we were able to carry out the entire project very efficiently. In late August, the first samples were produced and measured. We can now begin series production.”