At Technology & Innovation (T&I), Ralf Maisack is the expert on lightweight robots (cobots) and mobile robots (AGVs and AMRs). He makes the case for consolidating robot requirements and adopting uniform technologies.

In T&I’s product finishing panel, Ralf Maisack is the expert on several finishing processes, including engraving and greasing seals and fitting them with springs. “I have worked at Freudenberg since 1988. Since then, I have been dealing with automation, first in special machine construction and then at T&I from 2010 on,” he said.

Over the past few years, the panel has also focused on FST’s use of robots. “Robots are basically used to speed up processes, boost efficiency, and reliably maintain quality. The efforts often involve increasing job safety as well, while freeing staff from largely monotonous activities that are hazardous to health or ergonomically unsound,” Maisack said. He has created a table showing which Freudenberg Sealing Technologies (FST) facilities use which types of robots. “As of 2022, 950 robots were in use at our sites worldwide,” he said.

Most are industrial robots. At an often breathtaking pace, they independently perform a wide range of work steps with tremendous agility, with technical safeguards to protect employees. Six-axis robots are the standard for fast, repetitive assembly and joining tasks during medium- and long production runs. Four-axis robots, the so-called SCARAs, are not quite as agile, but they are well suited for pick- and-place assembly work on one selected plane.

Maisack is keeping a close eye on two other trends. First of all, lightweight robots, so-called cobots, which cooperate with people in a work process without a protective barrier. Their major advantage: They are comparatively easy to program and operate. They can also be used flexibly when they are individually equipped with the appropriate “end effector” or gripper. The built-in safety sensor system makes sure they do not get in people’s way in the shared workspace.

Two Sides of the Same Coin

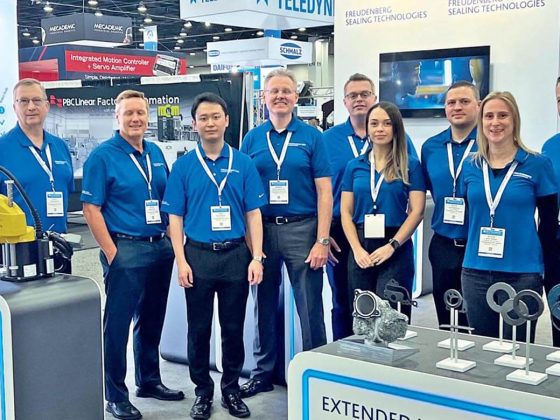

FST, a robotics customer on one hand, has nearly 900 industrial robots, more than 50 lightweight robots (cobots) and more than 20 mobile robots worldwide. The numbers are rising. At the same time, FST supplies robot manufacturers with sealing solutions. These numbers are rising as well. In meetings with robot manufacturers when he was a prospective customer, Ralf Maisack has even brought in FST sales representatives to present the company’s products. “One of our suppliers had to replace seals at our company. I connected him with our sales team so they could offer the manufacturer high-quality FST solutions.”

Cobots Behind Bars

Their disadvantage: They generally work more slowly and with less lifting capacity than industrial robots. The use of cobots requires an elaborate risk analysis to ensure worker safety, and it must be regularly upgraded. That is why cobots were on the agenda at a recent gathering of European HSE officers in Opatovice nad Labem in the Czech Republic. Some FST sites even prefer to operate their cobots “behind bars,” screened off from employees to avoid the need for risk analyses.

Mobile transport robots, the second trend, are joining cobots on the plant floor. They can be found at several FST facilities. Various versions of these robots mostly transport pallets or boxes full of parts from point A to point B, preparing the way for forklift-free factories. Automated guided vehicles (AGVs), which travel on predetermined routes, are in wide use – as are autonomous mobile robots (AMRs). Although managed by a fleet manager, they function autonomously. “The highest use would be a combination of both trends – lightweight robots installed on AGVs or AMRs,” Maisack said.

As manager of the finishing panel, he advises FST on the selection of appropriate lightweight and mobile robots. He is putting his faith in uniform technology from one manufacturer. “In special machine construction, I saw the many benefits of bundling requirements and using the same machines for the same processes as comprehensively as possible. That applies to robots, too. We can then buy them at lower cost, and maintenance and repairs are uniform and thus less complicated. And we can connect them to our IT networks everywhere in the same way.”

He is happy to field questions from anyone interested in these topics. For example, Maisack has created a potential assessment that can be used to figure out whether the use of a lightweight cobot for a specific purpose makes sense.