The Lead Center Integrated Molded Components (IMC) offers a wide range of parts for medical devices, especially for electric toothbrushes and valves – with steadily growing success.

Fluid Handling is one of our core strategic segments because it is building a bridge to a wide range of other industries,” said Christian Jaschke, Manager, Product Marketing, at the Lead Center IMC in Kufstein. Aside from the auto industry, general industry and especially pharmaceutical and medicine technology are some of the sectors.

Valves are needed everywhere. They dose liquids and gases or regulate their flow. Sealing technology “made by IMC” is irreplaceable in valves. Some examples are magnet armatures that move axially, along with valve tappets and plates, seal nipples, and tilt and plate anchors. The Lead Center’s core competency is in composite parts. Here an elastomer and an insert piece made of plastic or metal form lasting, strong connections. The business often involves very small, invariably customer-specific parts with appropriately tight manufacturing tolerances. It is precision work.

In “Health & Safety” applications, these components from the Lead Center IMC are used in respirators and blood pressure measurement devices, dental drills, anesthetic vaporizers, dialysis equipment and respirator masks. In incubators, they supply premature infants with the right amount of oxygen. “We provide a wide array of products for medical technology applications, generally to equipment manufacturers,” Jaschke said.

An Old Workhorse Is Making Giant Leaps

The seals that the Lead Center has provided to the electric-toothbrush market leader for two decades are like an old but still incredibly agile workhorse. The steed is now making longer leaps than ever.

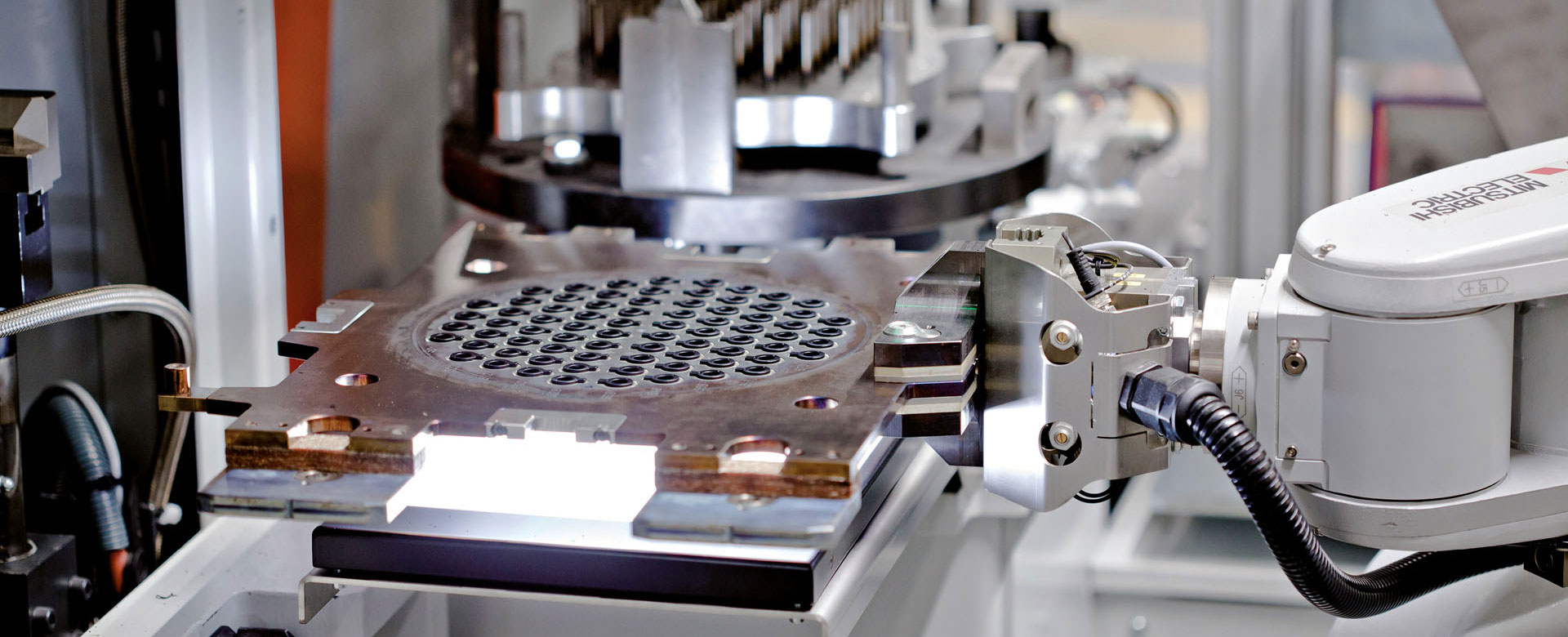

For one thing, shipments of these tried-and-tested seals have now climbed to than 50 million units annually. To handle the huge quantities, a second fully automatic manufacturing facility with a second-generation production architecture has gone into operation in Kufstein. A word of explanation: Beneath the pin where the toothbrush head is attached, the sealing bellows makes sure that the mix of water, toothpaste and saliva does not penetrate the toothbrush. This reliably protects its electronics and mechanical operation.

For another, the Lead Center IMC is now developing a bellows with the same function for a new, advanced model from the same manufacturer. For the first time, an additional elastomer component is being used to seal the drive unit in the product, a premium electric toothbrush. The seal is also in development and could open up a new chapter in the ongoing story of the Lead Center’s dental care successes.