Due to the COVID-19 pandemic, people have become more aware of the importance of the pharmaceutical industry and effective medicines. For Freudenberg Sealing Technologies (FST), pharma is a promising growth market where expertise, quality and trust count for a great deal.

More and more people live on our planet and growing numbers of them are elderly. This is boosting the demand for medicines as well as food – whether for the treatment of acute and chronic ailments, or for preventive care, in the form of vaccinations, for example. The world is increasingly becoming health-conscious.

Even before the COVID-19 pandemic, Freudenberg Sealing Technologies put a stronger focus on the pharmaceutical industry, seeing it as a potential growth market where FST has still not exhausted its opportunities. Like the food and beverage and chemical sectors, the pharmaceutical industry is one of the process industries that are a special focus of FST’s Freudenberg Industrial Services.

The factors that have made FST successful in the food and beverage industry for years are similar to those in the pharmaceutical industry. To exaggerate a bit for purposes of illustration, the facilities of the two target sectors could theoretically bottle similar products given the fact that they often have the same components. That’s because stringent hygiene requirements or CIP/SIP resistance to aggressive cleaning media are some of the common features that run across both of the process-industry segments that FST is eyeing. That’s also the reason nearly the same materials and products have applications across segments. FST’s white compounds offer a distinctive characteristic that is especially in demand in the pharmaceutical sector; they do without the admixture of carbon black. Even with mineral fillers, they offer the required thermal and chemical properties.

Upon closer scrutiny, the purity and quality requirements in the pharmaceutical industry are especially high. Human lives are directly at stake. Ultrapure end-products are the focus here. “Trust and reliability are the most important aspects of the pharmaceutical industry. Customers appreciate our years of engineering and technical experience in the development of highly resistant materials and seals,” said Nicole Schneider, Vice President, Global Process Industry.

Inoffensive Seals, Better than the Competition

In pharmaceutical production and processing, the end-all and be-all is for the ingredients in a seal compound not to leach out and potentially cross into the product and impair its effectiveness. FST has investigated this deal-breaker in leachable and extractable studies of different materials and has proven their inoffensiveness. The results were outstanding compared to competitors‘ materials. “You have to invest ahead of time and demonstrate that your own products meet the requirements,” said Mike Minow, Key Account Manager, Process Industry Germany. He calls this the “price of admission” to the market segment. Another FST advantage is the global availability of its products, since major pharmaceutical companies operate globally.

These FST materials naturally conform to the regular industry standards and have the right approvals. “It is also important for us to be able to offer a detailed traceability of their individual ingredients down to the last gram,” Minow said. Logistical services such as individual packaging are considered an absolute necessity in the pharmaceutical industry. Together with a commercial partner, FST offers digital package labeling that discloses approvals and certificates at the click of a mouse.

A word about FST’s commercial partner: FST works with the Mühlberger Group in the pharma segment. A strategic FST partner, it focuses on pharmaceutical technology, among other specialties. It is also extremely well-connected and opens doors for FST to pharmaceutical companies and manufacturers of installations, machines and components. The two strategic partners team up to solve customers’ problems. Late last year, FST and Mühlberger also invited companies to exchange views and information in a digital pharmaceutical dialogue. FST is keeping an eye out for other strategic partnerships offering market expertise as the Mühlberger relationship does.

Products & Applications

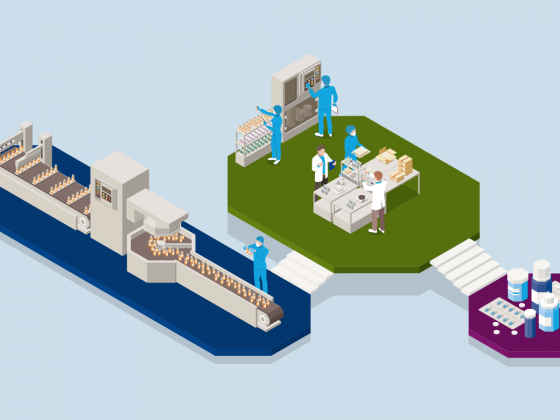

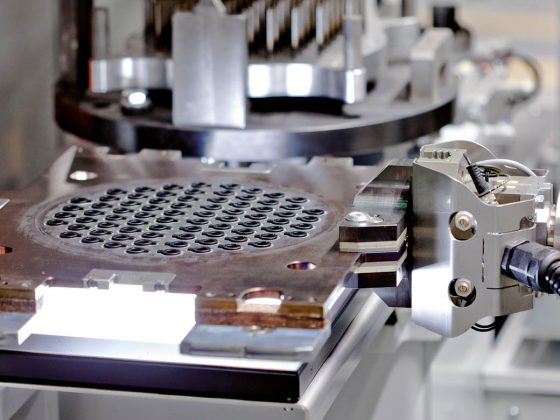

Solid medications are frequently coated by “coaters.” This makes them easier to take and more resistant to moisture, oxygen and light. They also provide protection against damage during packaging and shipment. In some cases, the coating has the effect of slowing the delivery of the active ingredient to the body after ingestion. FST provides Hygienic Usits® for these coaters, which prevents the buildup of microbes under the screw heads, along with profile seals, O-rings and V-rings, and inflatable seals.

In addition, a wide variety of standard seals and special, customer-specific products are employed in mixers, tablet presses, filling machines, granulators, sterilizers, homogenizers, containers and tanks. Clamp seals are a classic: They ensure that tube lines between flanges are securely connected with one another. Many FST parts, such as pump and valve seals, and diaphragms, are used elsewhere in the process industry as well, not just in pharmaceutical equipment.