The hydrogen economy is offering Freudenberg Sealing Technologies (FST) opportunities beyond electrolysis and fuel cell applications. Hydrogen must be highly compressed for transport from one location to another, and for storage. FST is now focusing on high-tech, high-pressure seals for piston compressors.

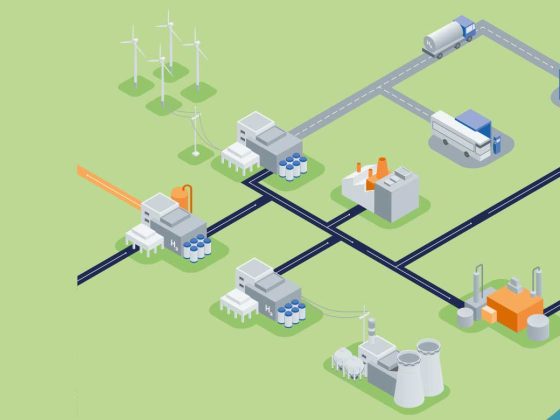

Under the prevailing conditions on our planet, hydrogen is a colorless and odorless gas. One of its hallmarks is extremely low density. That means hydrogen takes up a great deal of space, much more than natural gas, for example. This feature affects its transport via pipelines or trucks on its way from its production site to the end-user. Similarly, its voluminous space requirements have an impact on its interim storage on route and final storage in tanks – whether in a local heating plant, at a fueling station or in the tank of a fuel cell-powered truck.

The smaller the volume to transport or store, the more efficiently the gas can be handled. The compression of hydrogen under high pressure – up to 1000 bar – is required to conserve space. By comparison, when we go to a service station to check the air pressure in a car’s tires, the measurement device generally displays between two and three bar. It doesn’t take much imagination to see the enormous challenges that seals have to endure in compressors – ideally over at least a year of continual use until the next scheduled maintenance.

“Different technologies are being used in the standard compressors for hydrogen applications today. There are components in each of them that we can optimize with our know-how. Based on in-depth dialogues with our customers, we are now mainly focusing on high-pressure applications in piston compressors,” explained Dominik Schneider, Sales Segment Manager, Fluid Handling Technology, Europe, at Sales General Industry (GI).

The technology can be used very flexibly. It features a piston that moves up and down to compress the gas. The hydrogen must not evaporate or penetrate the sealing material. There is one critical condition – a high degree of wear – produced by the high pressures, temperatures, and sliding speeds. These speeds occur at the high contact pressures that the seal applies to its counter surface. Wear is especially a problem in these kinds of oil-free, dry-running compressors.

Competitive Advantages

“There is still no sealing system that meets the required service life and operates reliably. For the most part, the sticking point is finding the right sealing material. We have to rethink things completely at FST. But especially in these challenging, high-pressure applications, we can exploit our know-how in materials, design and scalability, from extremely small to large-scale production volumes. These competencies are our competitive advantage,” Schneider said.

He points out there are other encouraging factors promoting the success of new high-tech sealing solutions for compressors. They include, first of all, close interdisciplinary cooperation with customers; second, multifaceted options for inspection, testing and analysis, including computer-supported simulations and computing methods carried out by FST and Freudenberg Technology & Innovation (FTI); and third, sharing knowledge and experiences with corporate siblings Klüber Lubrication and EagleBurgmann.

One thing is certain: The piston seal will be free of persistent per- and polyfluorinated chemicals, or PFAS, which could harm people and the environment.