From cobots to transportation systems: Freudenberg Sealing Technologies (FST) shows the versatility of its robotics solutions on its company website fst.com

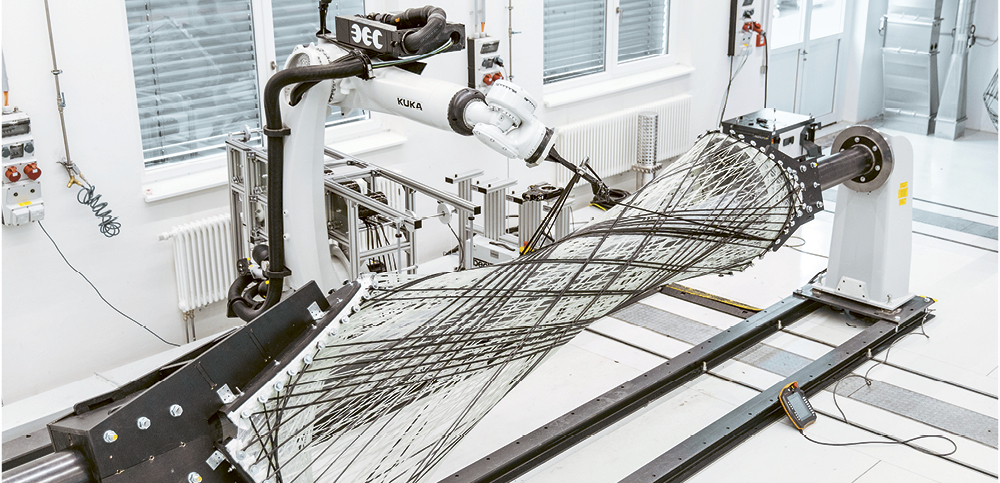

Modern production processes have become inconceivable without robots.

They lift, assemble, transport and perform multiple other functions in industrial manufacturing. From high-precision tasks in electronics production to handling heavy loads in harsh environments, robots often work under extreme conditions. It takes more than just intelligent controls and powerful drives to ensure that they function reliably. One frequently overlooked but crucial factor is the right seal.

Every motion counts and must be protected

Seals perform an important task in robots: They protect sensitive components from dust, moisture, heat and cleaning agents. At the same time, they must enable movements with high speed and precision. The requirements vary greatly, depending on where and how a robot is used.

Cobots: multidirectional joints, IP protection, low friction

Collaborative robots move along multiple axes, work in close proximity to people and have particularly stringent sealing requirements. Rapid movements can generate temperatures of up to 60 °C in the joints. Ingress Protection Seals for Robots (IPSR) have been developed specifically for outdoor applications: They are IP65-certified, protect against dust and water splashes and keep the frictional torque low, which is important for precision and safety during collaborations. The special geometry of their sealing lips adapts to complex arm movements – unlike conventional O-rings, which are unsuitable for multidirectional motion in tight installation spaces. The low-friction design also ensures an immediate response in the event of safety-critical emergency stops.

SCARA, Delta and 6-axis robots – varying requirements

Requirements for seals differ significantly depending on the type and area of application. SCARA robots often handle precise assembly and pick-and-place tasks. In these applications, chemical resistance, compressive strength and thermal stability are particularly important.

Delta robots, in turn, combine high speed with precise positioning, requiring seals that can reliably support dynamics and accelerations.

Six-axis robots are especially versatile: They often operate under extreme conditions such as heat, lubricants, abrasive particles, and intensive cleaning cycles in industries ranging from automotive production to food processing.

AMRs (autonomous mobile robots) are widely used in internal logistics, where robustness as well as resistance to temperature fluctuations, aggressive cleaning agents and disinfectants are essential, especially in hygiene-critical areas.

Seals and materials from Freudenberg Sealing Technologies for robotics

Freudenberg Sealing Technologies offers a broad portfolio of seals and materials developed specifically for robotic applications. These include the Premium Sine Seal (PSS), which extends the service life of components through low-friction sealing and protection against internal contamination, the eCON fleece designed to protect electric motor bearings, and the Modular Plastic Sealing Concept (MPSC), which reduces weight and installation space through a modular design. In addition, standard oil seals and customized O-rings are used to meet diverse requirements.

The selection of materials is tailored to each application area and includes EPDM, FKM, PTFE, PEEK as well as Fluoroprene XP. These materials are resistant to high temperatures, chemicals and mechanical stress. The aim is to extend service life, reduce maintenance costs and lower the energy consumption of robotic systems.

With new content on its website, FST makes robotics visible

To give customers a clearer understanding of these various solutions, the Robotics Sales team and the Marketing & Lead Generation team have completely revised and restructured the website content on robotics.

At https://www.fst.com/markets/robotics/, a comprehensive overview is now available:

- What types of robots exist and what are their special features?

- In which sectors are they used?

- Which specific seals does FST offer in this area – and why?

It’s worth taking a look!