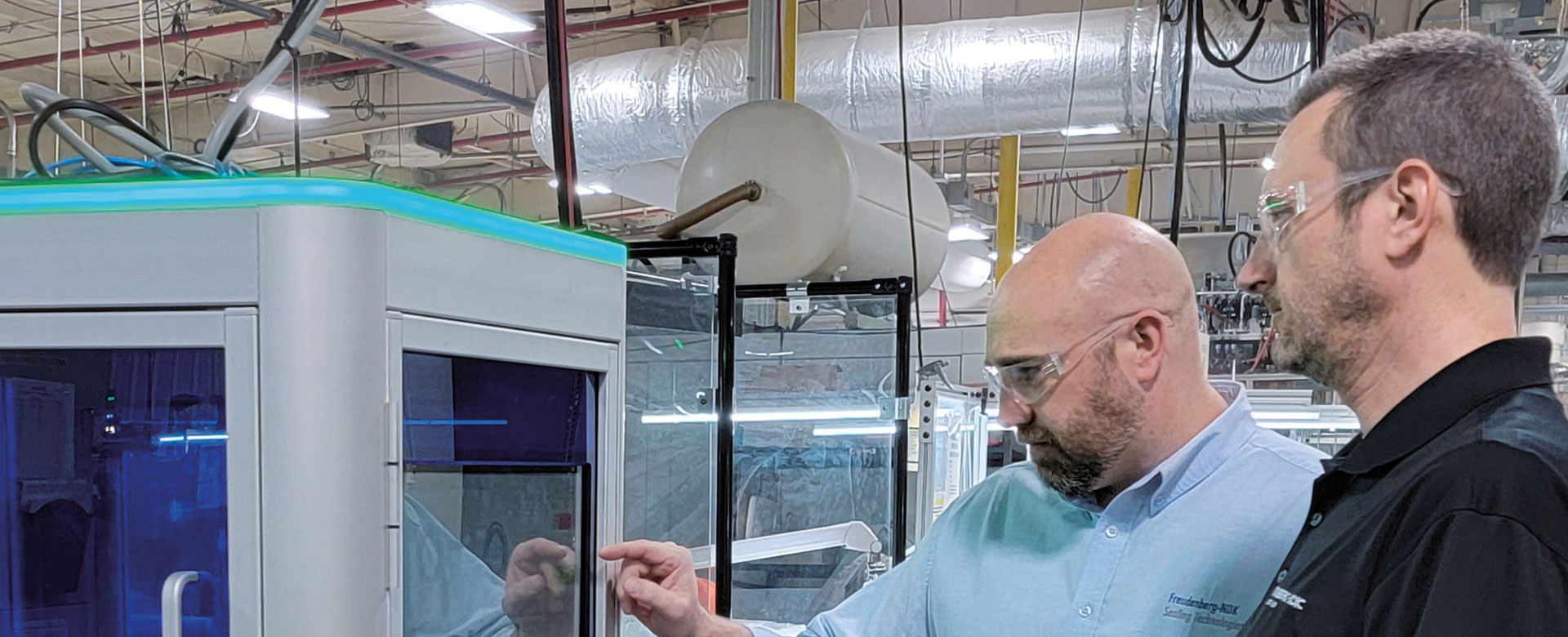

In Morristown, Freudenberg Sealing Technologies (FST) has installed a newly developed, fully automatic visual inspection system, strengthening its claim to “zero-defect quality.” This state-of-the-art system can inspect small parts at significantly greater speeds. Developed and built by the company’s engineers, these machines are smaller as well as more flexible, efficient and cost-effective than commercially available inspection devices.

Zero defects. Period. Such demanding requirements have long been the price of doing business for automotive suppliers. And delivering top-quality parts is even more challenging today as product designs become more complex, production rates accelerate and the penalty for failure is magnified.

“There is absolutely no room for product defects,” explained Robert Scavuzzo, Vice President of Freudenberg Sealing Technologies’ (FST) Global Advanced Manufacturing Technology (AMT) group. “Customers want perfect parts every time. It’s up us to get the job done and do it efficiently and cost effectively.”

Within FST, he said, this means continually updating processes, making timely capital investments, and developing new technologies, including advanced automated machine vision inspection systems. To this end, AMT has been working with company engineers in North America and Germany to develop a new automated inspection system. The first unit was installed in FST’s Morristown, Indiana, plant in early January, with another unit to quickly follow.

Automation Required

In early 2021, Morristown won a contract to produce 10 million cartridge seals per year for a global automotive customer. There was little time for celebration as the plant’s focus quickly shifted to prepping for production launch to meet the customer’s timeline. During prototype production, engineers realized that the plant’s existing inspection technology couldn’t handle the complex seal geometry, or the speed of the injection-molding process required to produce the cartridge seals.

“These parts are incredibly challenging,” said Mike Vieth, FST’s Manufacturing Engineering Manager in Morristown. In addition to being extremely small, he noted, the cartridges are asymmetrical and have six sealing surfaces instead of the typical two surfaces. The production equipment, itself, presented its own challenges, with high cavitation and five-

minute mold cycles.

“It was clear that we needed a more advanced inspection system than we had been using,” Vieth concluded.

Morristown first began using automated inspection systems about 20 years ago. These off-the-shelf systems could detect a few simple defects, such as flash, underfills and material splits or tears, explained Advanced Manufacturing Specialist Jeff Ellenberger, who has worked at Morristown for 22 years.

When it came time to replace these machines in 2017, Freudenberg worked with a different equipment manufacturer to provide an improved system that included specialized software and lenses that could detect material leakage and other flaws.

“This was a huge step forward in technology,” Ellenberger recalled. Still, the plant realized that further development would be needed to meet increasingly stringent customer requirements.

Team Approach

At the same time that Morristown was tooling up for the new sealing program, AMT was developing its next-generation machine vision technology. The highly customized FST system promised to be more efficient, significantly smaller, and less expensive than previous inspection units.

The development process was led by Dr. Helmut Hamfeld, Senior Engineering Specialist, AMT, who works in Weinheim. He was joined on the project by Scott Sulhan, a Plymouth-based senior engineer who specializes in robotics and mechanical engineering.

The pair worked closely with Ellenberger to tailor the new inspection system for the Morristown application. In addition to comprehensive product specs, they documented all the potential cartridge seal defects the system could encounter and would need to identify. This allowed them to teach the system the difference between good and bad parts.

Once the unit was programmed, Morristown began sending prototype parts to Germany for testing. The result? “The system caught every defect as intended,” Vieth said. “It was amazing.”

Perfect Timing

“Helmut and Scott were developing and building a more precise and flexible inspection system just when we needed it,” Ellenberger noted. “Not only could we easily adapt it for our application, it also was significantly smaller and much more affordable.”

Sulhan built the inspection unit in a month using about 40 machined parts. It was shipped to Germany for final testing and passed with flying colors. The unit was then shipped back to the U.S. and sent to Morristown in early January.

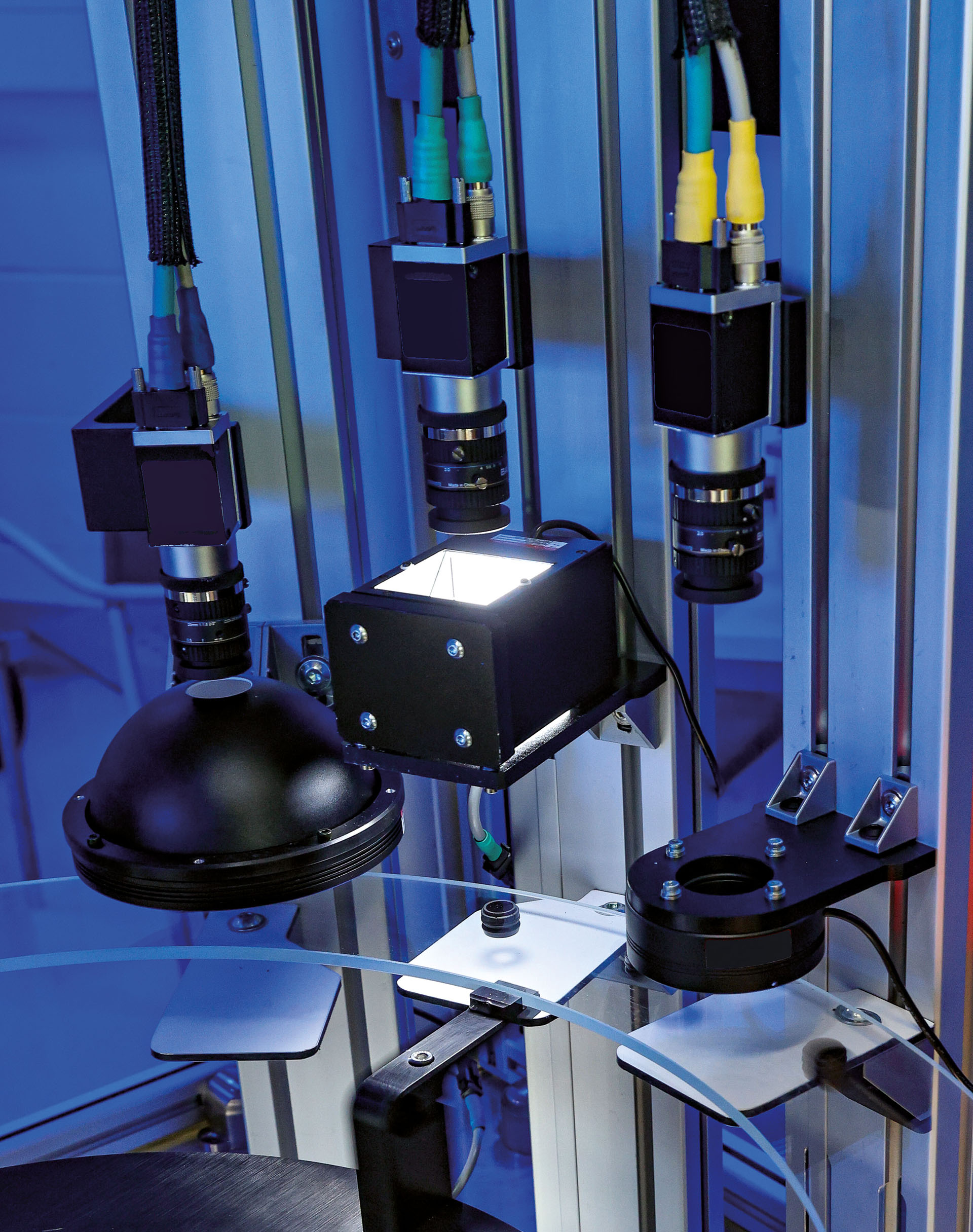

The next-generation machine, dubbed FVision GP 50, combines proprietary vision control technology with advanced automation. Measuring just 30-by-30 inches (76-by-76 centimeters), (not including feeder and packaging components), the unit is a third the size and cost of currently available automated inspection machines.

Freudenberg plans to use FVision GP 50 to inspect a wide variety of small parts (up to a 50 millimeter diameter), including small automotive seals, springs and O-rings that are made of different types of materials and use different production processes. It features new image processing technology – including the ability to self-adapt to process variations – and can support as many as four cameras.

FVision GP 50’s glass-plate design allows cameras to simultaneously photograph seals from multiple angles – including from the bottom up – to avoid unnecessary handling. The Morristown unit will conduct more than 20 different surface inspections at a rate of up to 10 parts per second, depending on feeding rates and other variables. The unit also distinguishes between actual defects and random process variations such as those caused by dirt or dust.

A Nod To Industry 4.0

Most FST vision control machines are connected to a database that produces live status information about process and machine conditions, Scavuzzo explained. In a nod to Industry 4.0, FVision GP 50 is the starting point for a closed-loop production system where injection machines continuously monitor and adjust themselves during operation to maintain product integrity and eliminate defects.

FVision GP 50 will also play an important role in FST’s efforts to standardize equipment and processes throughout its production facilities. To this end, Scavuzzo estimates that the new inspection unit could eventually be used in about 80 percent of the company’s plants with minimal design changes, and customized camera, illumination and software capabilities that support specific applications.

“Equipment suppliers don’t understand our products, production processes and challenges as well as we do,” Scavuzzo noted. “Using our own engineers and scientists is a key competitive advantage that enables a deeper commitment and understanding of our own systems, and FVision GP 50 is a huge step in that direction.”