For decades, Freudenberg Sealing Technologies (FST) has been devoted to the science of developing the right rubber compounds for seals. FST’s success story is built on first-class elastomers designed and produced in-house, along with made-to-order rubber-metal composite parts. At the same time, FST is expanding its portfolio of materials. New materials with specific characteristics are required for emerging markets and applications in batteries, fuel cells and electrolyzers. Materials development remains the key to the company’s success in the future.

Alternative to PFAS-based Materials

An In-house Development to replace PTFE

FST has developed a hydrolysis-resistant, high-performance polyurethane that offers significantly better properties than conventional variations of PTFE. Hydrolysis refers to the breakdown or destruction of chemical bonds – in this case, those found in sealing materials – in reactions with water.

FST originally developed the new material for mobile hydraulic applications for use in construction machinery in regions with high atmospheric humidity. In line with the expected use, the high-performance polyurethane withstood a baptism of fire in a piston seal for construction equipment. There are now inquiries from other industries as well.

There are many different reasons for this: For one thing, it is an impressive material due to its outstanding qualities, including its performance and resistance to media and abrasion. It also allows low-friction seal geometries that are hydrodynamically optimized – something that has been not feasible until now. Not least of all, it offers a low-cost alternative to per-and polyfluoroalkyl substances (PFAS), which have come under criticism. The alternative meets stringent legal requirements.

Reducing the CO2-Footprint of Polymer

Of Eucalyptus, Sugarcane and Wheat Chaff

FST has made a commitment to become climate-neutral by 2045. The development of new materials can help reduce the CO2 footprint of FST’s products. The company is exploring sustainable substances that can replace components in polymer compounds – usually mineral filler to promote strength and rigidity – that, so far, have come from fossil materials.

FST’s research and development labs in Plymouth, Mich., in the U.S., have compiled a list of sustainable ingredients and their potential sources: calcium phosphate obtained from bone ash, an antioxidant from eucalyptus plants, rapeseed oil, beef tallow, fillers made from lignins, which are important for the compressive strength and resistance of plant-based tissue, sugarcane, wheat chaff and recycled rubber … they can all be processed into ingredients for polymers. This assumes that the sustainable materials guarantee the same performance the seals have had in the past. They have to pass comprehensive tests and evaluations to prove they are suitable for the application. Another assumption is that the sustainable material can be obtained without interruption and with equivalent quality long-term.

Incidentally, in 2015, FST introduced an EPDM partially made from sugarcane byproducts. The market was not quite ready for it at the time. Today customers increasingly want to know what sustainable materials FST can offer.

Accelerating Vulcanization without Health Hazards

Sustainable Standards

FST has developed elastomer compounds that do without ethylene thiourea (ETU) in the production of the synthetic rubber chloroprene. ETU is considered a potential health hazard. In the absence of alternatives, ETU has been the standard option for accelerating the cross-linking of rubber to this point.

FST’s innovation is already proving itself in real-life applications, specifically in series-production cars. Customers confirm its performance, which satisfies increasingly stringent requirements. The auto industry is using the new ETU-free products in boots for joints in tie rods, suspension arms and control arms. The boots protect moving parts from outside influences and keep lubricants from leaking.

FST is not just pursuing its own sustainability goals. It is one of the pioneers in the development of new, ETU-free elastomer compounds and is considered the benchmark in the field.

Simriz® FFKM in High Demand in North America

Faster Availability

In North America, the demand for high-quality perfluoro elastomer compounds from FST’s Simriz® family has more than doubled over the past two years. The premium material is highly regarded for O-rings, seals and diaphragms for safety-critical applications in the aerospace industry, fluid handling, agriculture and the construction sector.

There are different reasons for this: The high-quality and extraordinary technical performance of the material. Simriz® surpasses every other FFKM on the market, and this helps customers avoid expensive downtime. The patented cross-linking structure, chemical stability and elasticity of the FST elastomer provide protection under extreme conditions. Those characteristics help it resist aggressive chemicals, high pressure loads, and temperatures up to 325 °C (617 °F), among other influences.

FST can also score points with customers on another front: Simriz® compounds have been immediately available – even during supply chain disruptions when other FFKM products were not on the market. The reason: FST is vertically integrated down to the material’s base monomer, putting the entire production process in its own hands. It can thus provide standard replacement seals within a few hours.

In response to the latest successes, FST is installing a new production cell for the high-tech material in its O-ring plant in Santa Ana, Calif., U.S.

A Thermoplastic to Withstand up to 1,200 °C

A Hot Topic

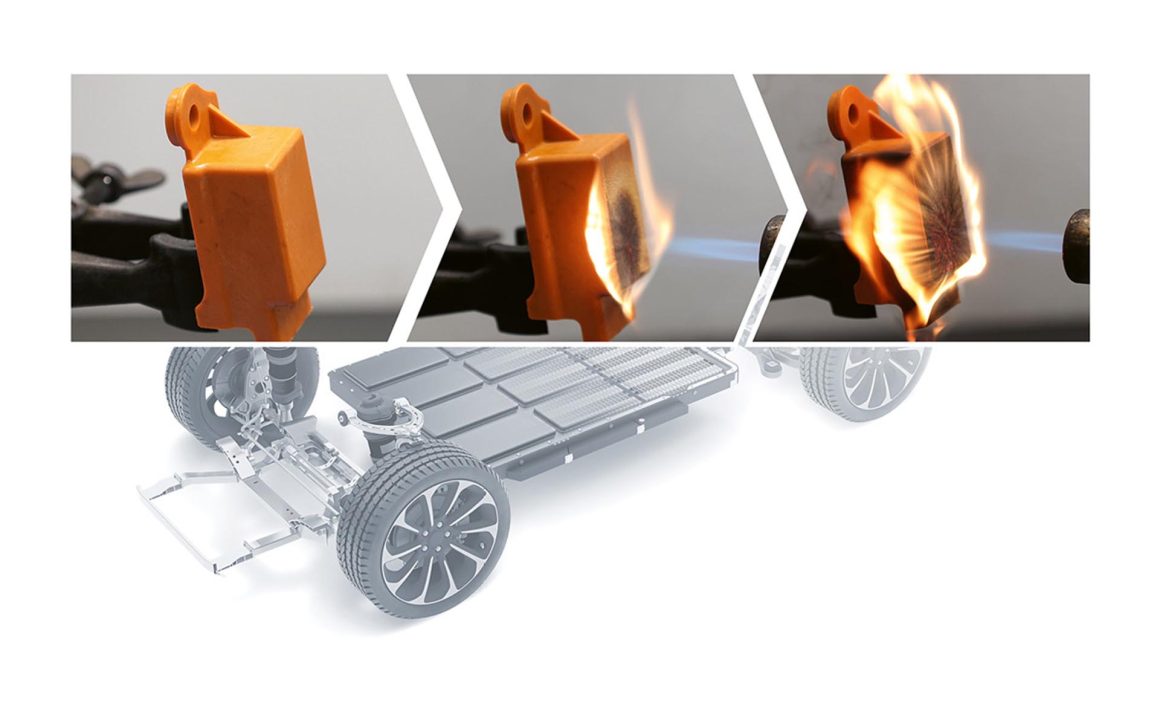

FST is helping to improve the fire safety of electric cars with a new class of materials called Quantix ULTRA. It will not melt or ignite at temperatures up to 1,200 °C (2,192 °F).

Quantix ULTRA materials are lighter than their metal counterparts, reducing a vehicle’s weight and the amount of energy it consumes during driving. They are also a flexible option, allowing complex geometries for a range of applications with high standards for fire safety and weight. Quantix ULTRA is now being used in series production for the first time, serving as a flame protection barrier for parts in the cooling systems of lithium ion batteries in electric cars.

Quantix ULTRA is easily processed at high volumes with injection molding. FST’s patented cross-linking process promotes its efficient production. Its basic material is a temperature-resistant thermoplastic. A targeted mixture of fillers boosts its mechanical stability, enabling it to withstand enormous heat. The cross-linking of the plastic molecular chains guarantees that the component retains its shape even under extreme conditions. Its material properties can be adjusted for the particular application.

New Test Lab for Batteries in the U.S.

More Data for Better Batteries

FST has bolstered its research and development presence in Plymouth, Mich., U.S., with an advanced battery test lab costing several million dollars. The new facility makes it possible to test batteries with high energy and power densities, along with their components. Thermal runaways can also be simulated.

“This is how we learn and how we capture the data that flows into the development of our products and materials. There are many applications and dynamic sectors that benefit from these materials,” said Chad Bauer, Senior Vice President of Technology and Innovation. “Our experience with material development for fire safety and thermal applications began more than 20 years ago with our products for the aerospace industry, and we are building on this expertise for applications in electric mobility.”

Designed by Explosives Expert

The new test facility includes two square, 14.5-cubic-meter test chambers made of steel in a reinforced testing room. Designed by explosive experts, the chambers house cells, modules and batteries during thermal testing. The chambers are designed to withstand thermal events in individual cells, modules and battery packs of up to 25 kilowatt hours. This is equivalent to the force of several kilograms of TNT.

A range of measures guarantees safety inside and outside the lab and the building. The environment has not been forgotten: A multistage exhaust gas system filters out gases and particles that escape batteries during thermal events.