The Professional Association of the Raw Materials and Chemical Industry has paid tribute to the Freudenberg Sealing Technologies (FST) plant at Reichelsheim, nominating it for the “Job Safety Wins!” award. At a private exhibition scheduled for September at Hannover-Langenhagen, the nominated companies will be presenting their projects to a jury. The winner will get a 12,000 euro prize. In all, 21,000 euros in prize money will be awarded.

NC lathes are used in the PTFE Business Unit of the Lead Center Special Sealing Automotive in Reichelsheim for processing PTFE tubes internally and externally and for parting rings. “The latter involves the use of a scalpel-like knife that is very sharp and pointed. When the operators convert or clean the machine or change tools, they don’t have much room to work. There is the danger that the knives will cut their fingers, hands or forearms accidentally, causing injuries,” said Goran Odobasic, Manager, PTFE Business Unit. These cuts are sometimes deep and almost always require a visit to a physician or hospital. They often require stitches.

Since the problem first occured, the Reichelsheim team has gone all out to protect employees. “For starters, we have cut-resistant safety gloves, of course, for the employees to wear when they work on an open machine. But the knives are so sharp that they can cut through gloves, even those with the highest protective rating,” said Felix Halter, who is in charge of Health, Safety & Environment (HSE) at the Reichelsheim plant. “The next attempt was a magnetic cover. This was certainly a more stable option, but the knives still cut through the material and broke when they came into contact with the cover.” So these measures were insufficient.

A 3D Printer Helps Out

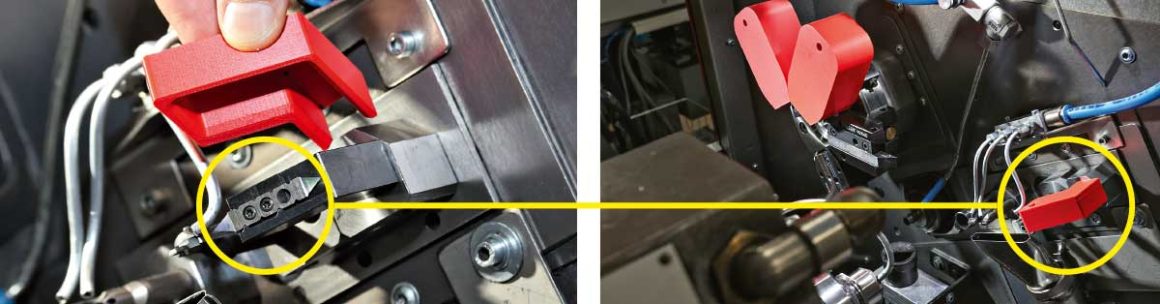

The solution came from a brainstorming session that Process Technician Uwe Franzmathes, Production Technician Sergej Schmidt, Halter and Odobasic attended. It was a plastic protective piece adapted precisely to the various knife holders. It is easy to put on and remove. “This completely covers the blade, allowing employees to clean the machines or replace parts or cutting steels without the risk of injury,” Franzmathes said. The plastic’s red color is easily visible and sends the important message that it has to be removed before the machine is started up. If this is overlooked, only the cover is broken, not the tool or the machine, unlike its magnetic predecessor.

Another plus: Schmidt created a CAD design that was used to print out the different plastic covers with a special 3D printer when, for example, one of them breaks and has to be replaced. “It took eight to nine hours to print one of the larger covers. For the smaller ones, we were able to produce 10 units at a time,” he said. There is also good news on the sustainability front: The plastic used for the covers can be easily recycled.

Another consideration is its overall effect. Since the new safeguard has been in use, there hasn’t been a single cut injury in the PTFE Business Unit. The previous total was about 20 per year, causing a few injury-related lost workdays. Thus, within the full meaning of the Freudenberg Guiding Principles, both the company and employees benefit.

The Professional Association of the Raw Materials and Chemical Industry has nominated the project for its “Job Safety Wins!” award. At a private exhibition in Hannover in September, the Reichelsheim team will present its results to a jury. For now, these innovators will be crossing their fingers and hoping to win the main prize of 12,000 euros. But they have already gained something important: zero cut injuries.