Corteco’s revenue has continually grown in recent years – and it is expected to stay on the same course in the future. Even today, its warehouse in Hirschberg is operating beyond its capacity. In the medium-term, the e-transformation will have an impact on the replacement parts business, and more space will be needed. The existing lease in Hirschberg runs out in 2026. A decision had to be made on a location for the warehouse and the company’s next steps. The Weinheim Industrial Park, the seat of the Freudenberg Group, was selected as the new site.

Consider a familiar scenario: You have to take your car to a repair shop. A part has to be replaced. And the work has to be done as soon as possible, not four weeks from now. To provide that service, the availability of the part at the repair shop and at an upstream distributor is crucial. This is where Corteco comes in: The Freudenberg Sealing Technologies (FST) subsidiary supplies the independent automotive replacement parts market, offering more than 26,000 items in OEM quality. Of that number, about 16,000 are in the company’s European Central warehouse in Hirschberg – primarily seals, vibration control products, and interior air filters. About 100,000 parts per day are shipped off to customers from the site.

The current Hirschberg distribution center was built in 2013 on a roughly 9,000-square-meter (97,000-square-foot) site. Corteco has seen above-average growth in recent years, and the warehouse will soon no longer be suited to its mission. Employees have had to improvise in many cases, adapting their processes or outsourcing tasks to service providers. This in turn has led to higher shipping costs and longer lead times, and forced a decision on the best path for the future. With an expansion in Hirschberg out of the question, Corteco drafted plans and concepts for a new building. In the end, the Weinheim Industrial Park was selected as the location since it offered many infrastructure-related advantages such as an autobahn connection. The groundbreaking is scheduled for early 2024 and the move-in for mid-2025.

Corteco is also adding an area to the new location where it will be able to assemble and package parts on its own. That means that activities that were outsourced due to limitations on space and capacity will be coming back. Here’s something else to keep in mind: More than 95 percent of the parts sold by Corteco are assembled into kits. This may involve removing the parts number from the product or giving the items special Corteco outer packaging.

Energy-Efficient Robots In The Autostore

“Customers do not tolerate partial deliveries from different sites. They want everything in one package from a single source. At the same time, shipping costs would wipe out any price advantages if assembly operations were transferred to potentially more affordable locations. And we would be slower and have longer lead times. Especially in the replacement parts market, this would put us at a competitive disadvantage. It’s not an option,” said Dr. Wolfgang Lohmann, Director, Operations Europe.

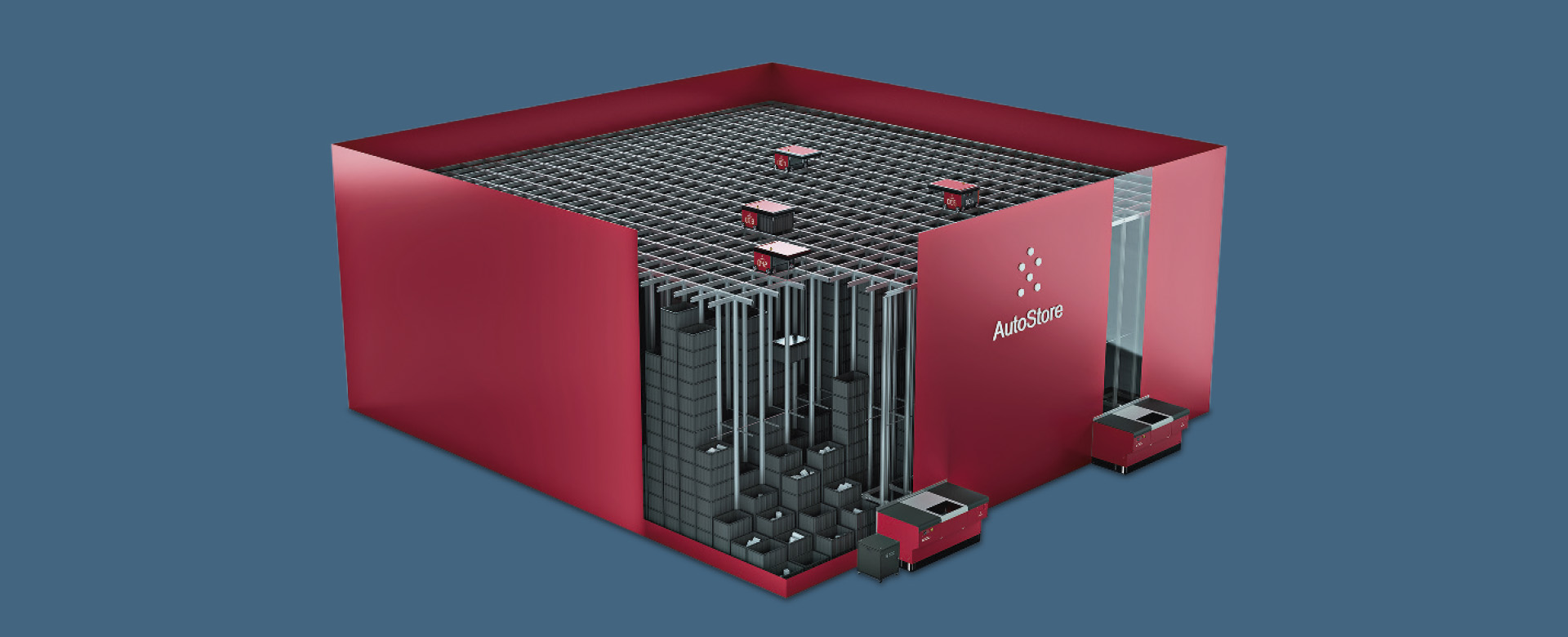

One area of the new building will be a high-bay warehouse, and another will be a so-called AutoStore system. This space-saving, semiautomatic system reduces space requirements by nearly a third. Its robotic processes take over physically difficult and routine tasks, saving time and space. That means employees can focus on activities that require know-how. “A full 99 percent of all the items that we sell can be stored in the AutoStore system. It can be expanded at any time, even during ongoing operations, without activities temporarily coming to a halt,” said Project Manager Jan Mittelstädt.

AutoStore has another upside: It is supported by energy-efficient robots, 10 of which consume about as much energy as a vacuum cleaner. They “see” in the dark without difficulty, do not require wide aisles, and find articles quickly. “The items come to the person, not the other way around,” Mittelstädt said.

Sustainability does not come up short either. For example, a photovoltaic system will independently supply the new warehouse with a substantial portion of its electric power. The packaging concept is also being redesigned with the goal of “even less plastic.”