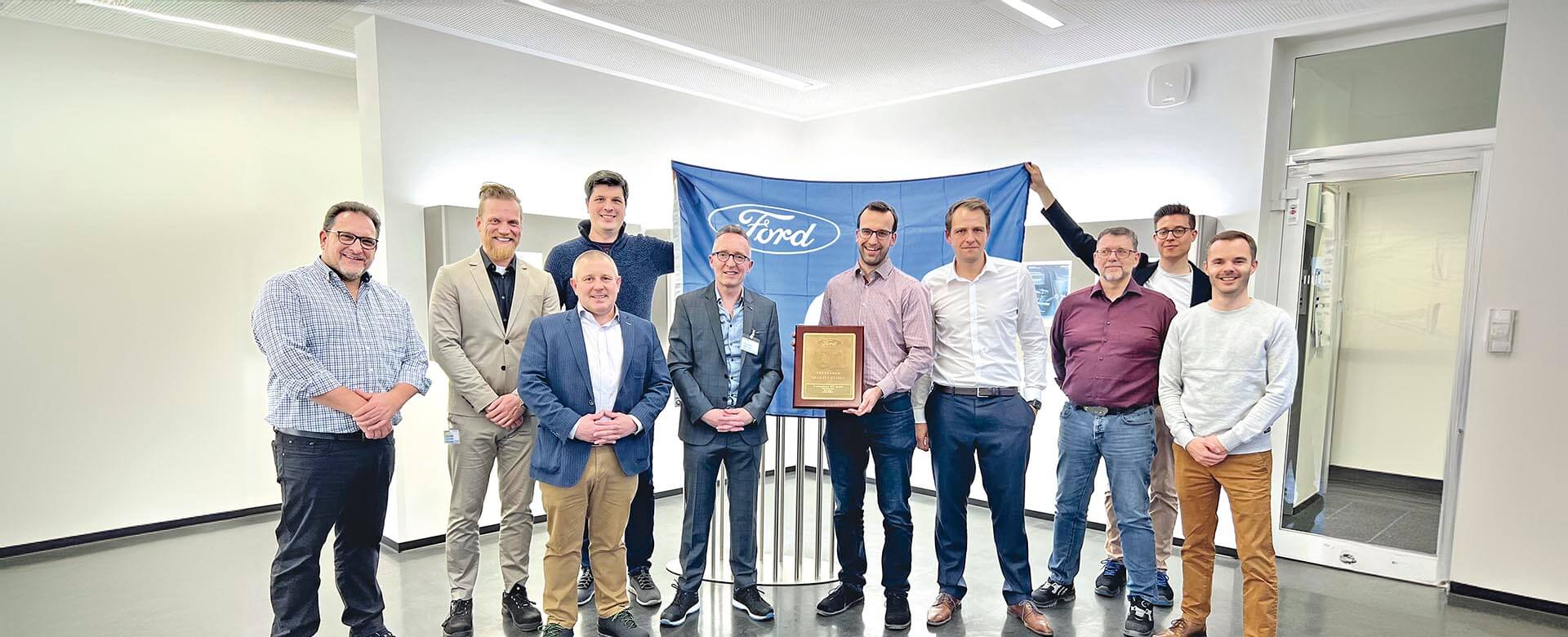

The Ford Motor Company has presented its Q1 Award to the Freudenberg Sealing Technologies (FST) facility in Reichelsheim. Highly regarded and prestigious, it is the highest honor that Ford bestows on its suppliers.

In early February, Ford Motor Company presented FST’s Reichelsheim site with a Q1 Award, paying tribute to a rigorous two-year effort and opening doors to promising future business. The golden plaque is the car manufacturer’s recognition of top product quality, on-time deliveries, operational efficiency and sophisticated internal processes.

The production of the DIAvent family played key role in the launch of the Q1 project at Reichelsheim. Since the Special Sealing Automotive (SSA) Lead Center at the site has been supplying Ford for a long time, the process targeted the entire location. “The certification process took two years,” explained Alexander Schork, Supply Chain Manager at the Lead Center Diaphragms & Boots, who oversaw the effort. “It involved answering six master documents and 50 questions, some with various subsections, on the topics of quality, development, product marketing, production, purchasing, and supply chain management.”

Two critical factors were decisive. The automotive industry requires a consistent level of performance for the material flow across the entire supply chain. The Materials Management Operations Guideline/Logistics Evaluation (MMOG/LE) serves as the global standard for the evaluation of supply chain management processes. This standard has already been established at FST for years. The second factor is called Material Planning & Logistics – and this is where FST has broken new ground.

Award Indispensable For New Business

Schork said the Q1 Award from Ford is more than an accolade for volume suppliers to the automaker. It is basically indispensable for securing new business in the future. With this certification, Ford wants to make sure that suppliers understand all the processes and portal applications that it has defined. They then must be integrated into their processes to meet stringent customer requirements.

For FST, this certification clears the path for future business with Ford. The company now exclusively awards significant projects to Q1-certified suppliers. Another benefit: “We can certify our processes and product samples ourselves, so we no longer need an evaluation from Ford. That is a huge vote of confidence,” said Schork.

Certification In Record Time

“At the award ceremony, Ford’s leading supplier developer lavished praise on the team in Reichelsheim and everyone at FST who contributed to the success. He said it had been a long time since he certified a supplier who navigated the process as successfully as we did,” says Daniel Uhl, Marketing Manager at the Lead Center Diaphragms & Boots. It took FST employees just two years to secure the certification. “Others take up to five years and often still fail in the end,” Schork said.

The success can be attributed to the collaboration of various disciplines that extend beyond Lead Center Diaphragms & Boots and SSA in Reichelsheim. Significant contributions were made by colleagues from Sales, Customer Service and Corporate EDI (Electronic Data Interchange). “The award from Ford validates the dedication with which our employees focus precisely on what our customers need and expect – then they even surpass these expectations wherever possible,” Uhl said.