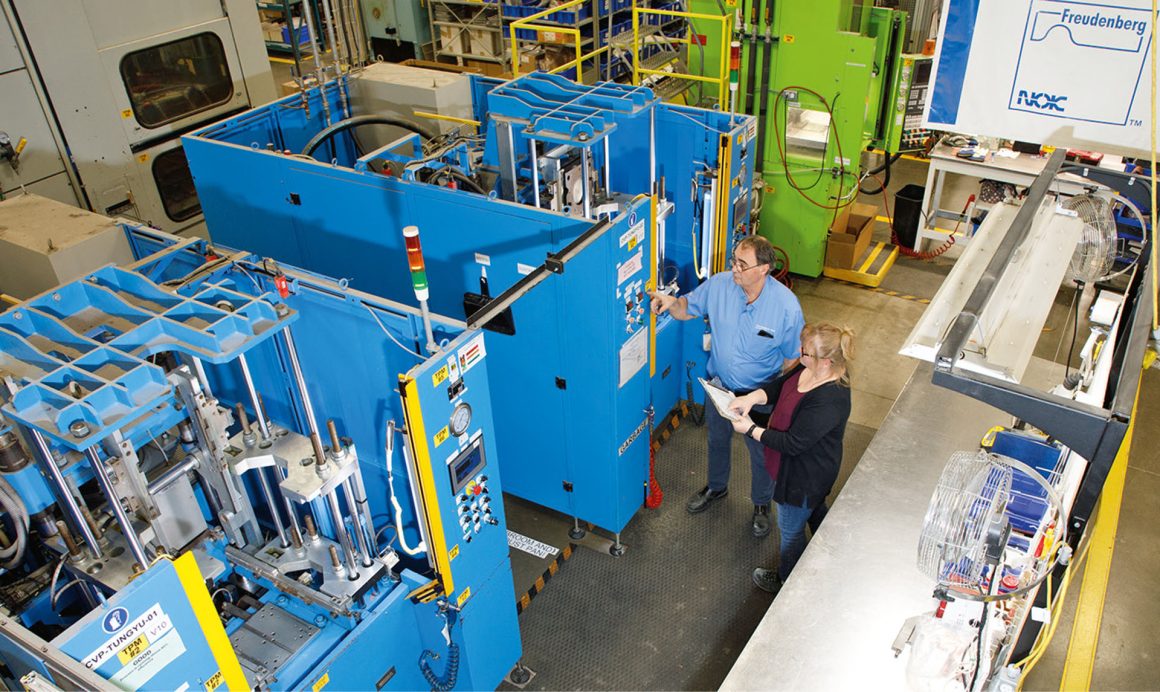

Even when a facility is in a region committed to sustainability goals, as the Freudenberg Sealing Technologies (FST) plant in Tillsonburg is, complacency remains a risk. It is important to be aware of day-to-day operations that affect consumption and be dedicated to continuous improvement in sustainability-related operations, no matter where your energy comes from.

The Tillsonburg plant is in Ontario, Canada’s most populous and manufacturing-heavy province. The area is also home to an abundance of natural resources. The combination of these factors has led to the province dedicating itself to several sustainability objectives, including CO2 neutrality before 2035 and net zero emissions by 2040.

Currently, the energy that powers Ontario is derived from a trio of sources, with about 51 percent coming from zero-emission nuclear power, 39 percent from hydroelectric power, thanks to the region’s abundance of waterways, and 10 percent from renewable (wind and solar) resources.

Freudenberg’s Tillsonburg facility in Ontario is automatically powered with this energy mix. But even though the region provides an eco-aware backdrop, the staff is still focused on improving its emissions and energy consumption numbers.

Good Energy Mix

The facility is not only dedicated to maximizing the measures already in place, said Terry Chute, Tillsonburg’s Health and Safety Manager. It is also looking for new ways to improve. “Based on Ontario’s energy mix, we come out pretty good on CO2 emissions as a whole,” Chute said. “But we were still being encouraged by the province to lessen the amount of electricity, overall, that we were using. Ontario was a little ahead of Freudenberg in terms of its goals, and this helped position us to respond to Freudenberg’s sustainability objectives when they were introduced in 2020.”

The Tillsonburg team has undertaken multiple efforts to improve its energy reduction efforts, first of all combining the facility’s two process cooling units into one. Previously, the plant had two systems, one for the LSR Molding cell and the other to cool the rest of the plant. This two-set arrangement not only doubled the cost of maintenance – it led to extra energy costs as well. A plan was implemented to remove the LSR cell-dedicated chiller and connect the other to the main HVAC system to create one overall system.

This downsizing effort has not only reduced maintenance costs but has allowed Tillsonburg to reduce its purchase of glycol, a type of antifreeze used in industrial refrigeration systems. As an extra measure, the plant now circulates the glycol that is used through the main air intake system, allowing waste heat to be reclaimed to heat the plant in the coldest months.

Another effort was reducing the number of variable speed pumps onsite from four to two. The original four pumps ran at 10 horsepower and operated in a constant-on state, whatever the demand. They have since been replaced by two newer pumps that have the ability to run at 7.5 horsepower at a variable frequency based on the specific demand.

Chute and his team also removed the liquid-cooled compressor that had served as the backup unit for the plant’s main air compressor and upgraded it to a GA22VSP variable speed air compressor. This upgraded setup allows the heat to flow out of the compressors to be collected and then partially heat the adjoining tool shop, keeping electrical and heating costs down. The system was also paired with a maintenance plan to prevent air leaks and keep it running efficiently, a vital part of the upgrade.

Investments Pay Off

Tillsonburg implemented other sustainability activities, as well. By replacing all of the existing lights in the facility with LED lighting that included automatic off/on sensors, the plant cut its electricity use by more than 259,000 kilowatt hours, saving $40,000 annually. “While the initial investment in LED lighting does come with a cost, it more than pays for itself when used correctly in less than two years’ time,” said Chute.

Other improvements include the reduction in size of the steam autoclave – which is the equipment system where parts and components manufactured onsite are cured – allowing it to use less steam to fill and maintain pressure during operation – and replacing the old fabric hand-cutters with equipment that has reduced material waste by nearly 20 percent.

Even with all these improvements, Chute says Tillsonburg is still thinking ahead and not resting on its achievements for too long. “It’s important for us to look for ways to reduce across all of the different areas of our facility,” Chute said. “When you take the collective sum of all these efforts, it becomes clear what an impactful difference seemingly small actions can have over time.”