Many of the parts that the Lead Center Special Sealing Industry (LC SSI) makes for Health & Safety applications are extremely small and require the greatest possible precision in tools and production processes. This applies to seals for dental drills and magnetic valves in respirators.

Who wants to go to the dentist – especially when the tooth trolls have been gnawing at your incisors, bicuspids and molars, and you foresee dental drills in your future? Today’s dental drills work at 350,000 revolutions per minute or more. We all know the sound, and none of us like it. It’s good to know that the drills can stop in an instant – thanks to a special seal from the LC SSI in Reichelsheim – if the dentist deems it necessary. In that case, it won’t keep running and penetrate too deeply into the tooth dentin.

The special seal has a double mission. First of all, it protects interior of the drill , keeping fluids and particles from penetrating it. Secondly, it functions as a brake. The drill is powered by compressed air moving through a turbine. During the drilling, a cushion of air is formed between the shaft and the seal. When the dentist pauses drilling, the compressed air stops, and the seal presses against the shaft and slows it with the help of frictional forces. It almost sounds paradoxical: The goal of the vast majority of sealing applications is to minimize friction. But in this case, friction is what the customer wants.

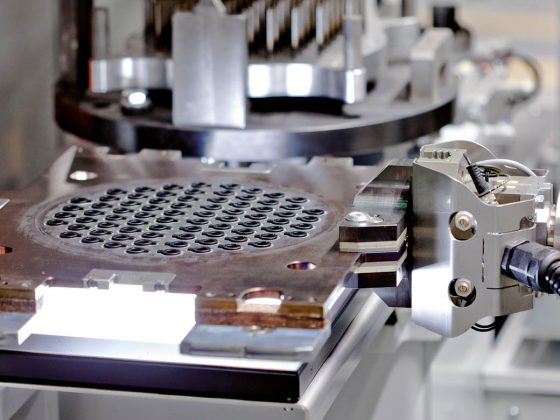

This is one of many medical-technology applications – whether in lab, anesthesia or other applications – utilizing LC SSI sealing systems. Another area of application involves elastomer composite parts for 3/2-way magnetic valves, which control the airflow in pulmonary ventilators. Especially at the start of the coronavirus pandemic, they were in high demand, far beyond the normal levels. Tobias Gutsch, Product Marketing, SSI, described one of the core competencies of the Lead Center: “These kinds of parts with extremely tight tolerances require precision tools and production processes,” he said.

Another competency is the ability to manufacture components in accordance with hygienic design, which is playing an increasingly important role in the pharmaceutical sector and beyond it. Here the requirements – cleanliness, along with resistance to cleaning and disinfection agents during sterilization, for example – for medical technology are hardly distinguishable from those for process technology. The LC SSI meets them with an array of high-performance materials such as PTFE and Simriz.

All in all, the flagships of the Lead Center include space-, weight- and resource-saving micro parts with minuscule diameters, sealing beads and wall thicknesses. In some cases, the Lead Center manufactures them in different, application-specific variations of the materials. When Dominik Linder, Product Development, LC SSI, looks off into the future, he talks about the first prototypes, now in the predevelopment stage, for micro pumps in portable insulin devices. Using new magnet technology, these pumps don’t merely dose in milliliters – the amounts are just a few microliters. By comparison, a droplet of water seems like a large lake.