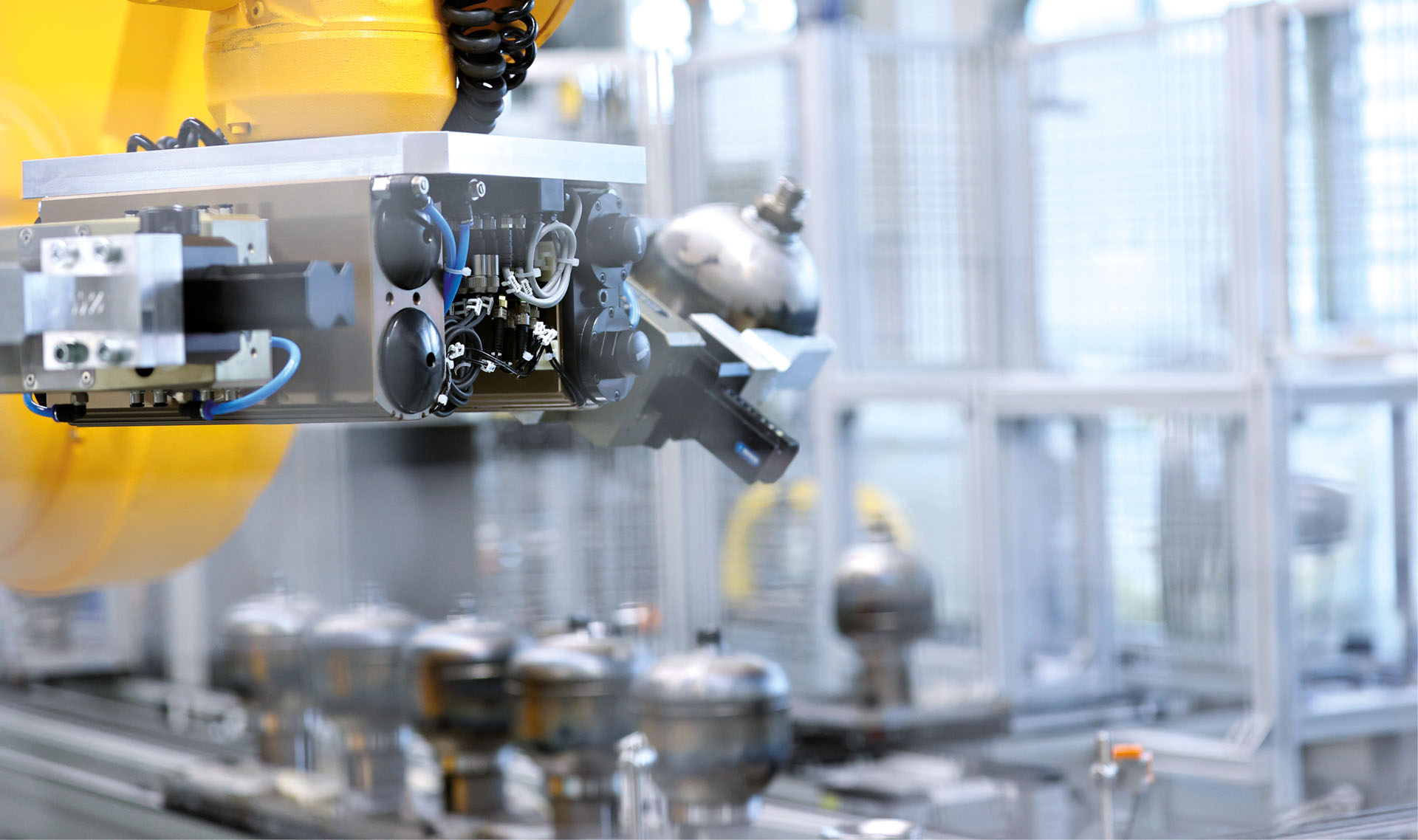

The Remagen facility has invested more than 1.5 million euros in advanced manufacturing technology. In a fully automated process, the new production line for diaphragm accumulators for industrial applications combines individual steps in the production process, from the welding of the shells to the labeling of the accumulators. Industrial robots make this possible. The technology is a milestone for the Accumulators Division on the path to Industry 4.0.

When a company spends more than 1.5 million euros to replace a 20-year-old production line, the investment should be tied to improved efficiency. “Per shift, we had been producing 310 parts from our main product group, the 1.4 liter accumulators. Now the number is 530,” said Operations Manager Marcus Darms, highlighting how the new line offers major productivity gains for many accumulator models. Workers had to wrestle with up to 17 tons of steel per shift, but two industrial robots help out today. They are giving employees massive relief from the physical aspects of these jobs.

The first fully automated production line at the Remagen plant has been operational since mid-May – at full capacity thanks to full order books. The startup occurred in stages. The next link in the production chain only followed when all the “growing pains” were remedied in an installation. The automation – tying the individual equipment from different manufacturers together – marked the final point in the process. “In this way, we were able to ensure that the whole line ran nearly problemfree right from the start,” Darms said.

Erecting a Monument

“Jürgen Klein and his team from Process Technology have built a monument to themselves,” said Operations Manager Marcus Darms. He praised the contribution of the many employees who worked on everything from the new production line’s conception to its startup.

A number of employees were integrated into the project in leading roles: Marco Oessenich, with his repair/maintenance team; Erich Körbel, ES Technology, and Business Unit Manager Tobias Weber, with his colleagues Eugen Fell and Stefan Grohs. It’s also important to highlight the fitters and other employees who worked overtime during the construction and startup phase, even coming in on weekends.

“Our coworkers in the purchasing department in Weinheim also were models of support. Monika Krajcovic and Claus Jöst, in particular, did a great job. Both had our backs and dealt with all the commercial questions so we could concentrate on technical issues in Remagen.”

Made-to-order

An electron-beam welding machine was the core of the investment. It was developed on a “made-to-order” basis with the supplier and accounted for nearly half of the total expense. It creates an inseparable combination of the upper and lower shells of the hydraulic accumulator. Electron-beam welding represents a unique selling proposition.

Another special feature is the ultrasound testing facility with integrated cooling. In a single work step, it checks the weld seam and cools the steel housing. Since 2012, the first generation of this kind of testing/cooling station – an in-house development – has been in use in another area in Remagen. A high-pressure test stand, another element of the new production line, is a special installation developed with the machine manufacturer.

Blueprint for the future

The buzzword Industry 4.0 not only applies to the two industrial robots that transport parts from one processing area to the next and load the machines in an automated process. Digitalization also encompasses the networking of the production technology and technical data, and their direct connection to the IT world. The data are pulled directly from the SAP system. Machines adjust automatically without manual inputs. Parameters can be easily scanned in.

The numbers say it all: The set-up at the marking station at the end of the process chain once took 20 minutes by hand. But now the product identification process is ready to go in just two minutes. The machine data are also captured online in the course of each production step. The information can then be immediately analyzed by process engineers and business-unit managers, and then readjusted when necessary. Logging machine data manually on paper is finally a thing of the past. The new production line is also a blueprint since the company will be outfitting other lines based on this model in the future.

Strengthening the industrial business

The hydraulic accumulators produced on the line are destined for the industrial sector, especially for farming vehicles. Diaphragm accumulators provide driving comfort on tractors – they handle cushioning and damping tasks at the front and rear axles, in some cases even on the entire chassis. With the auto industry in flux, these industrial applications are a supporting pillar for future growth.