Attending trade fairs, understanding and explaining product technology, scheduling meetings with manufacturers of farm machinery, and getting to know and understand all their equipment – it’s all part of the job for the agriculture sales team at Freudenberg Sealing Technologies (FST). But what exactly drives farmers? What does climate change mean to them? And what do planthoppers have to do with potatoes? Jens Wolfram, Global Segment Director, Mobile Machinery, used a personal connection to arrange for his team to visit a farm in Rheinhessen.

Klaus Weber is a farmer through and through. He farms about 100 hectares (nearly 250 acres) of land. His wife works with him, and his two sons, Niklas und Yannik, help out when they’re not busy with school work. In the winter, when there is little to do out in the fields, the family focuses on their machines, cleaning and repairing them, and ensuring that their tractors, combine-harvesters and the like are in working condition in the spring. And they restore tractors that have been in the family for decades. “Today’s tractors don’t really get very old anymore. In modern equipment, there are problems with their electronics sooner or later,” said Weber, glancing at his restored jewels. His oldest tractor dates back to 1958.

Cereals instead of Potatoes and Sugar Beets

Until a few years ago, the family grew potatoes, onions and sugar beets. But climate change has left its mark here as well. High temperatures, little rainfall and pests like planthoppers that spread in the increasingly mild climate have made both potato and sugar beet cultivation unprofitable. Planthoppers, an invasive insect species, carry bacteria that attack the crops. In the case of potatoes, they lead to so-called rubber tubers that are practically unsellable. The bacteria drastically reduce sugar content in sugar beets, sometimes by more than 30 percent. The chemicals used to fight the pests can only be applied in limited amounts.

There is another issue: As climate change increases the impact of solar radiation, potatoes are not tolerating the warmer conditions well. They need more water. “Locations near woodlands were previously considered less suitable since they shaded a portion of the plants. Today they are still producing excellent yields. Our potato yield was once 45 tons per hectare. Last year, it was 15,” Weber said. The family has learned to live with the climatic changes and has shifted to a different range of crops. Today cereals – wheat and barley – are growing where potatoes and sugar beets reigned a few years ago.

A “Who’s Who” of Farm Equipment Manufacturers

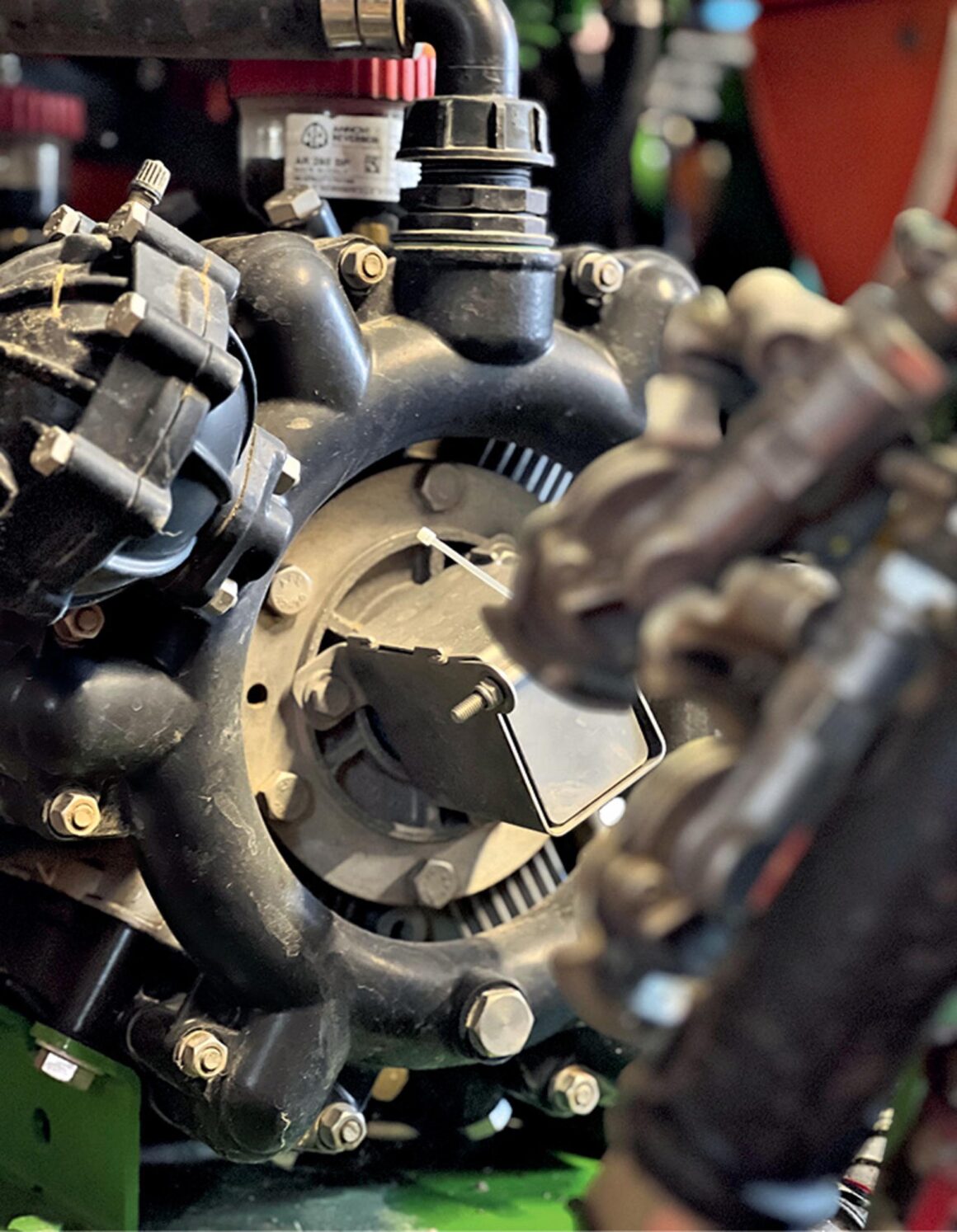

The family’s motor pool has a wide range of different tractors and agricultural machinery, which caused the hearts of the FST sales team to flutter. A combine-harvester is one of them – a Tucano from CLAAS, Armin Strunk, CLAAS key account manager at FST, pointed out during the quick visit to the farm. The other machines also represent a kind of “Who’s Who” of FST customers. Besides CLAAS, there are vehicles from Deutz, Fendt and Massey Ferguson.

Some farmers share expensive agricultural equipment. Still, the harvest depends on exact timing. When the wheat is ripe and the weather is good, every farmer in the region is in the same mode at the same time. So the run for the harvesters is on. That’s why the Weber family deliberately chose to have its own combine-harvester. The events of the summer of 2023 showed how farsighted this was. A long period of rain followed a week with warm, dry weather. If you didn’t bring your cereal crop in dry at the right time, you suffered substantial losses. The harvest would be getting moldy in the fields.

In October, the cereal seed is sown. Wheat and barley are harvested in early July. Unlike potatoes, cereals can be stored without difficulty. Farmers can wait for the right moment from the seller’s standpoint to sell their crops. Weber has already sold a large portion of the 2023 harvest, but a mountain of grain resembling a sand dune is still stored within a building. It contains 350 tons in a huge mound.

Incidentally, farming is becoming more and more digital. If you climb aboard a modern tractor, it feels more like the cockpit of a spaceship than the cab of a farm vehicle. There are four foot pedals, including two for brakes – one for the left side, another for the right. Joysticks provide precision control of devices like forage harvesters and presses. A smartphone serves as a documentation tool out in the fields. On the job, Weber uses it to enter what he has fertilized or seeded – and where and when he did it. Today’s tractors are equipped with GPS. The technology makes it possible for vehicles to drive nearly autonomously – thanks to perfect lane widths – and the seeds are sown precisely. There is hardly any overlap in the seeded rows. Property lines can also be determined precisely.

The visit to the Weber farm was an exciting opportunity for FST’s agriculture team to learn more about farm equipment in operation, see the company’s products such as seals and accumulators at work in the equipment, and become familiar with important issues in agriculture.