It was two years ago that Michael Müller, his American wife, and their four children moved from Germany to the United States. His new and old homes may be far from one another, but he has remained true to himself.

In Germany, Michael Müller initially worked in Automotive Sales at Freudenberg Sealing Technologies (FST). Later, in Reichelsheim, he worked on sealing technology at Fluid Power Automotive, mainly on applications for transmissions, air-conditioning, steering and shock absorbers. Today, as marketing manager, Fluid Power Automotive, he now works for Freudenberg-NOK Sealing Technologies (FNST) in Findlay, Ohio.

During the pandemic, Müller has been working two days a week in his home office in the university town of Bowling Green, a halfhour drive north of Findlay. When he looks out the window, he sees a true jewel that he designed himself and built with his own hands: a garden pavilion, also known as a gazebo.

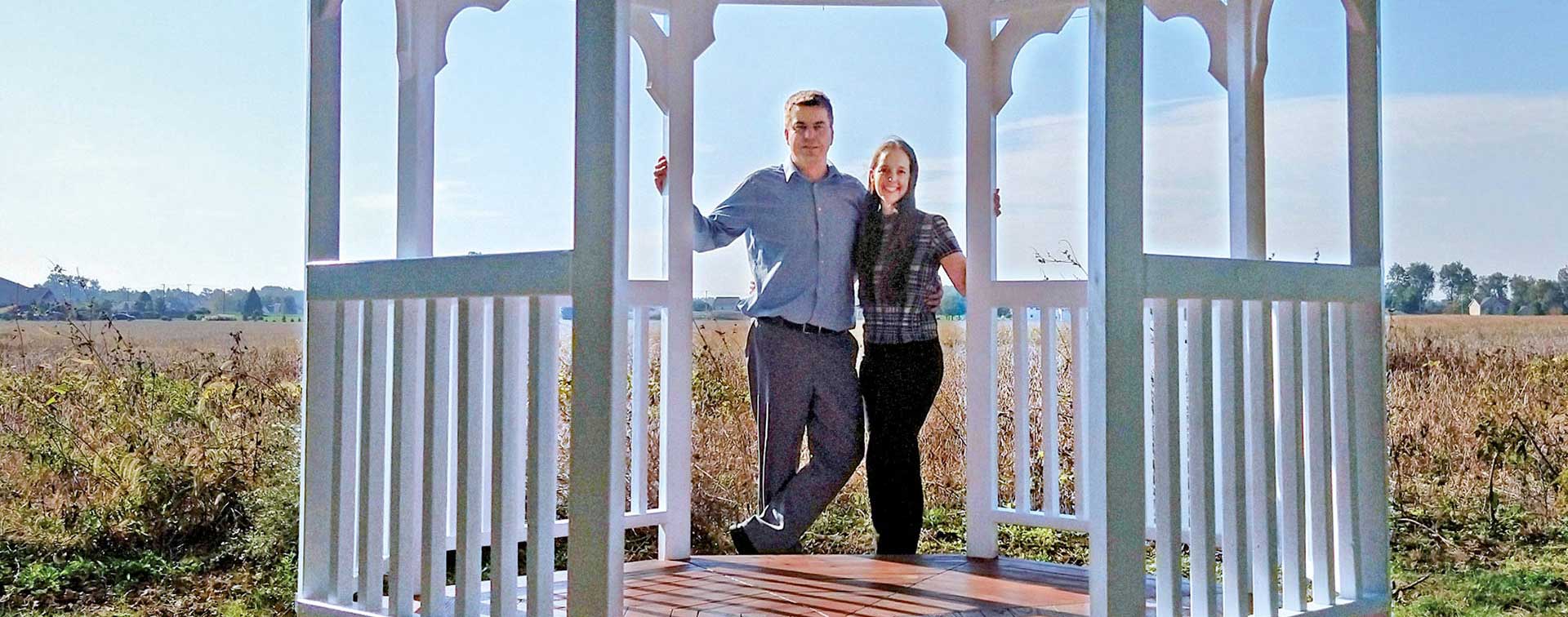

Image: Michael and Crystal Müller are pleased with their DIY-brand wooden pavilion.

A gazebo made of packing materials

The homemade structure has a number of peculiarities. Though located in Ohio, the gazebo consists almost exclusively of wood from the forests of southwest Germany. This building material in turn originally served as the overseas packaging for a Wickert press shipped from Germany. The press went into operation in Findlay in 2020.

“When I saw the wood lying behind the plant, I thought it was a shame to throw it away or burn it. So I asked whether I could take it home with me,” Müller recalled. He spent a few lunch breaks performing surgery on the beams and boards so they would fit in the trunk of his car. Once he brought it home, the materials – then freed of more than 1,000 nails – was first stored in his garage.

“I actually wanted to construct a wooden workbench or shelves for my workshop. But my wife had a better idea,” he said. She had really liked a gazebo that she had seen in a park, and she wanted one like it for their backyard.

Precision work

Müller was quickly persuaded. He grabbed a piece of paper and a pencil and produced sketches of a pavilion with an eight-cornered floorplan. In August, he went to work on the structure after acquiring the 120-volt tools, ranging from various saws to a plane, that he needed. “When you construct a large octagon, you become a devotee of precision. Exact work is the end-all and be-all,” he said, describing the role of a true craftsman. He then added: “The gazebo is really massive. It withstands the wind, which blows hard from time to time here.” He is especially proud of the intricate, eight-sided roof construction, supported by sixteen rafters that sit precisely at an angle of 22.5° from one another. And why are the eight rafters in the corners fulllength and why are each of the eight middle rafters shorter? “I wouldn’t have had enough wood otherwise,” Müller said.

The homemade structure, now painted totally white, has become a topic of conversation in the neighborhood. “Our neighbors from China have already offered to dedicate the gazebo with us over a cup of tea after its planned completion in October,” Müller reported at the end of September. Assuming the weather is good this fall, six to eight persons can be accommodated comfortably there. The response to his handiwork was also positive at the Oktoberfest in Findlay. The pandemic has long made it difficult to get together with locals and deepen social contacts in his new community. But the gazebo is now practically a catalyst for these conversations – and yet another reason to sustainably recycle valuable materials …