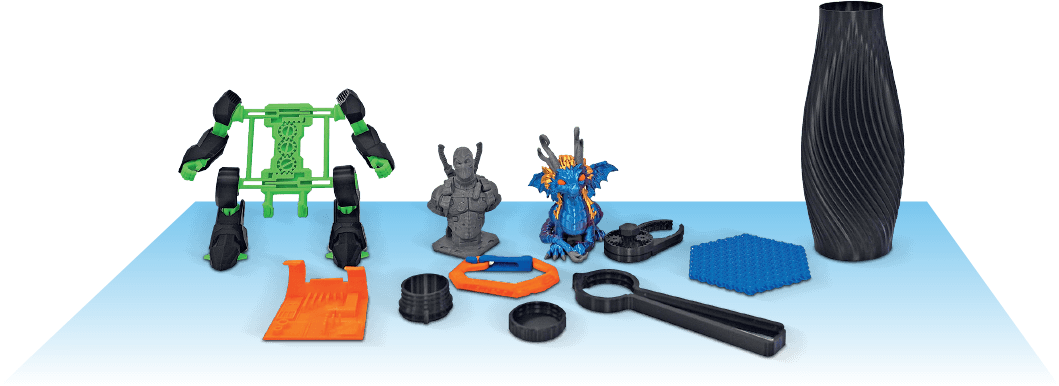

Marko Trutschel works as a CNC lathe operator at Freudenberg Xpress® at the Freudenberg Sealing Technologies (FST) plant in Schwalmstadt. In his leisure time, the self-taught expert in 3D printing explores the technology’s wide range of applications. From vases and spare parts for vintage vehicles to Christmas ornaments, he designs and prints anything that 3D printing can make.

Four years ago, 3D printing became Marko Trutschel’s new hobby and passion. “I had been an extreme athlete, competing in 24-hour mountain bike races. Then I had a very serious accident on my bike. My spine was broken, and I could no longer compete in endurance sports”, he said. “I suddenly had a lot of time on my hands and wondered how to occupy myself. I bought a simple 3D printer. I knew you operate it like a CNC machine,” explained Trutschel, who has worked as a CNC lathe operator since 2011.

In his leisure time, Marko Trutschel explores the wide-ranging possibilities of 3D printing.

He started out by learning the basics. “There are great instructions on YouTube. I was immediately hooked. My background is in plastics. and I quickly saw that a 3D printer can do almost anything,” he said. A trained precision machinist, he began making a wide range of products: vases, animal figures, carabiners, etc. “The stories about what I could design and produce gradually spread among my acquaintances. I’ve already printed vintage car parts that were not available otherwise. I look at the installation space, create the design, check the load with AI, and I’ve always found a solution.”

For greater flexibility in the use of color, he designed a custom-made add-on to his 3D-printer, allowing him to print with eight instead of four colors simultaneously. His wife has also benefited from his expertise. He designed an identification band for employees’ beverage bottles, and his wife’s company gave her a bonus for the innovation. “My wife also printed all the Christmas ornaments last year herself,” Trutschel, 42, said.

Trutschel also sees his workplace as a key area where the technology could be applied. “I’ve been telling my supervisor how great it would be to have a high-performance 3D printer in our department for some time,” he said. “If you can design a 3D model, you can print it. Especially for small, difficult, delicate items, 3D printing offers many advantages. It works faster, the risk of injury is much less, and it consumes almost no material beyond what is required,” he said.