Fortescue Future Industries is tackling the challenges of green hydrogen and renewable energy across a wide range of applications – and Freudenberg Sealing Technologies can contribute expertise to its success.

Fortescue is one of the world’s largest mining companies. Its name often comes up when the conversation turns to iron ore. In the primary economic sector, Fortescue is known as a leader in raw material extraction and production. Yet its subsidiary Fortescue Future Industries (FFI) is fully dedicated to renewable energy – and it’s going all out. “I have never seen this kind of speed or dynamism before in my career. It is unbelievable,” said Benjamin Crouch, Western Australia State Manager & National Business Development Manager at Freudenberg Sealing Technologies (FST).

The driving force behind this extraordinary commitment is the Australian entrepreneur and billionaire, Andrew Forrest, a large shareholder in FFI’s parent company, Fortescue Metals Group. Forrest has announced that he wants to produce 15 million tons of green hydrogen worldwide by 2030 (Source: Wikipedia).

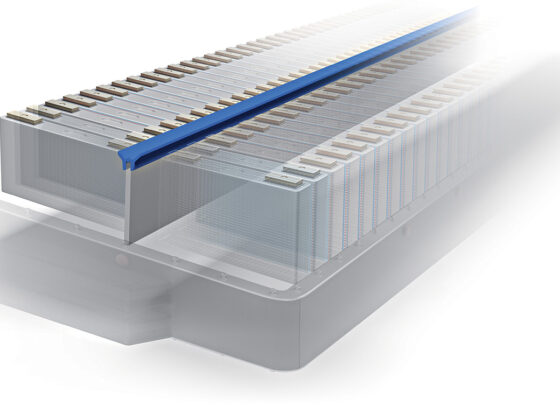

Crouch’s contacts with FFI only date back to the end of 2022. But the first contracts are already within reach. They will initially involve seals for various electrolyzer technologies for the production of green hydrogen. He would rather not say more, but he is expecting great things. “We are figuratively just scratching the surface. We still can’t see all the potential at Fortescue Future Industries. FFI is developing technologies and expertise in renewable energy along the entire value chain, from energy production, transportation, and distribution, all the way to storage,” he said.

Goal: Hydrogen cheaper than Diesel

FFI’s hydrogen and renewable energy projects range from solar and wind energy, hydropower, geothermal and fuel cell technologies, to the green energy sector (ammonia as an energy source). Its partners on these projects are spread across the world. “Making hydrogen cheaper than diesel” is one of the company’s ambitious goals. With this in mind, the parent company Fortescue has succeeded in “decarbonizing” its mining vehicles and operating them more cost-effectively.

Charlie Bilek, Vice President, Region Australia, is also optimistic that the cooperation between Freudenberg Sealing Technologies (FST) and FFI on the fifth continent will quickly bear fruit. “We are a strong partner with the right experience, flexibility, agility, development expertise, and capacity to innovate – with a global presence and global support. The first customer projects show that our materials expertise and our capabilities meet or even exceed FFI’s requirements,” he said.

A Customer Focus “Made in Australia”

To build its presence as a strong, competent partner in Australia, Freudenberg Sealing Technologies acquired a venerable local firm, Ludowici Sealing Solutions, in 2015. It has long been fully integrated into FST’s global network and is part of Industrial Services. FST Australia now has 18 employees.

In addition to a headquarters in Brisbane, it has three branch offices, in Perth, Sydney and Melbourne. From these locations, it offers high-quality standard and customer-specific seals under the Freudenberg brand as well as Dichtomatik-brand parts.

In Australia, FST is a full-service provider, offering sealing solutions for a range of market segments. including the food and beverage sector, heavy industry, agriculture, hydraulic operations and much more.