Freudenberg-NOK Sealing Technologies has secured significant new business to supply bumpers to a large American power tool manufacturer for use in its battery-powered nail guns. It represents a significant expansion of Freudenberg-NOK’s business in the North American power tool segment.

Freudenberg-NOK’s Troy, Ohio manufacturing plant will now produce 1.3 million bumpers annually to meet the customer’s requirements. The bumpers, approximately 1.5 inches in size, are being injection-molded using Disogrin 9250, a premium, Freudenberg-NOK-specific polyurethane material. Disogrin 9250 demonstrates excellent heat, fluid, and wear resistance. It handles pressure well and lasts longer than any other polyurethane material on the market. One important aspect is that the plant is supplying imperial-size (non-metric) components to support U.S.-based power tool production.

New business celebrated

Bumpers extend the life of power tools by preventing the piston inside the tool motor from striking the bottom of the cylinder and damaging the piston. They reduce power tool noise, impact, shock, and improve ease of use and safety for the operator. Troy recently celebrated the new business with a bumper launch party that included an opportunity for the associates to try the customer’s nail gun for themselves.

“This is a terrific win for Troy, and it’s important for our employees to understand how their work contributes to the success of the plant and the success of the customer,” said Jay White, Troy’s Competence Center Director for the Fluid Power Division. “We demonstrated total competence to the customer in areas such as engineering, design, materials, production and service. Moreover, pricing was appealing considering U.S. production in a competitive market. As a result, the customer recognized our market leadership, and we were able to replace an existing supplier and secure the business for Troy.”

While the Power Tools Segment is not new to Freudenberg-NOK, it is new in Troy. Opportunities to work with North American power tool manufacturers have been scarce. “In the past, we didn’t get many power tool inquiries, and when they did come in, they were for metric seals made of rubber. Troy doesn’t process rubber, so the work was sent to our Lead Center in Schwalmstadt,” White noted.

But the plant’s ability to injection-mold bumpers and other components in imperial sizes, coupled with its expertise handling polyurethanes like Disogrin 9250, worked in its favor.

Division and sales successful together

“The Troy team and Jay White have been doing a phenomenal job by supporting General Industry sales with engineering resources and material expertise to capitalize on new business opportunities,” said Miguel Oseguera, Global Segment Director, Power Tools. Oseguera pointed out that two of the largest power tool manufacturers in the world are based in North America. European and Asian manufacturers also have a production footprint in the region. “The Power Tools Segment didn’t have a dedicated sales force in North America in the past,” Oseguera stated. “Now we have a group of talented account managers in the United States who are coordinating business opportunities with local account managers. And the coordination between the Fluid Power Division and General Industry sales team has been the key to this success.”

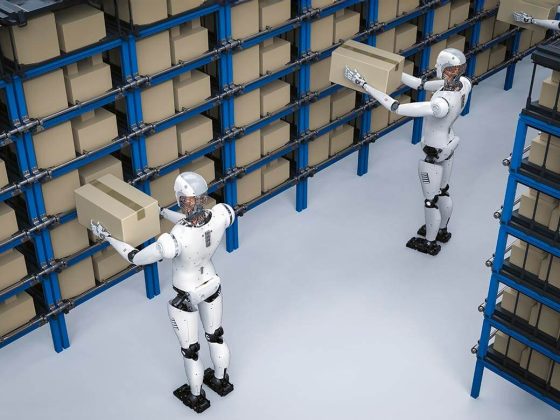

Troy has dedicated an entire production cell to the manufacture of the bumpers. In keeping with Freudenberg-NOK’s push for Industry 4.0 shop floor digitalization, employees revisited the cell’s production process and incorporated as much automation into its operations as possible. The cell runs autonomously without employees and bumpers, once molded, automatically fall into bins for shipping.

Automation to counter skilled labor shortage

This automation is not only producing consistent, high-quality parts, but it is also helping Troy address a plant challenge that many Freudenberg-NOK locations are struggling to overcome: a significant labor shortage.

“We have high labor dependency that we have been unable to rectify and solve so it’s important, as we bring in new business, to focus on new business that is not as labor intensive as our existing business,” White concluded. “The bumper cell is our kickoff to more autonomy. We are starting with these two machines but will replicate and build on this approach by applying it to other new business and cells. We want to use our people where we really need them by increasing automation that does not require a full-time attendant.”

Over the long run, White anticipates a successful, long-term relationship with its new power tool customer. “Bumpers have already led to other opportunities with the customer and other power tool manufacturers,” he concluded.